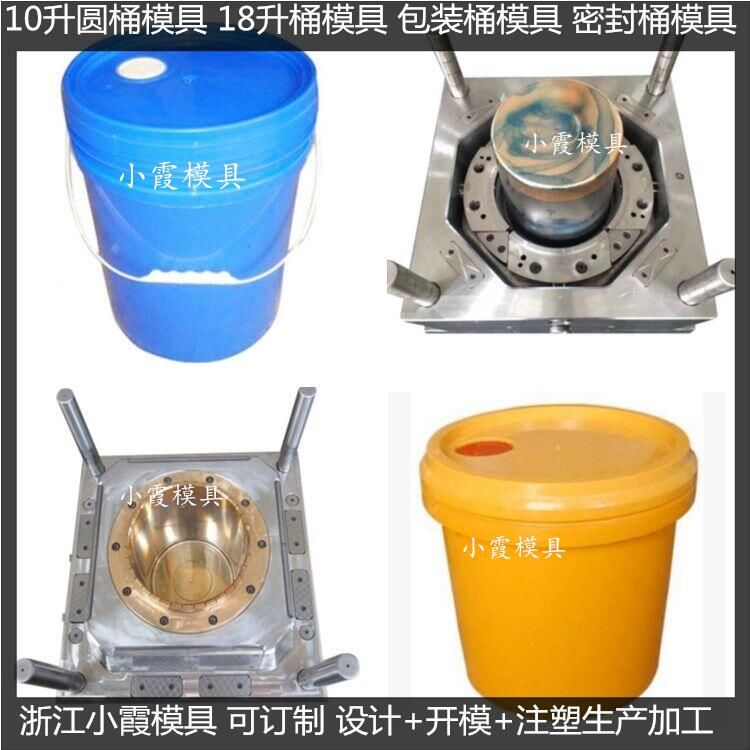

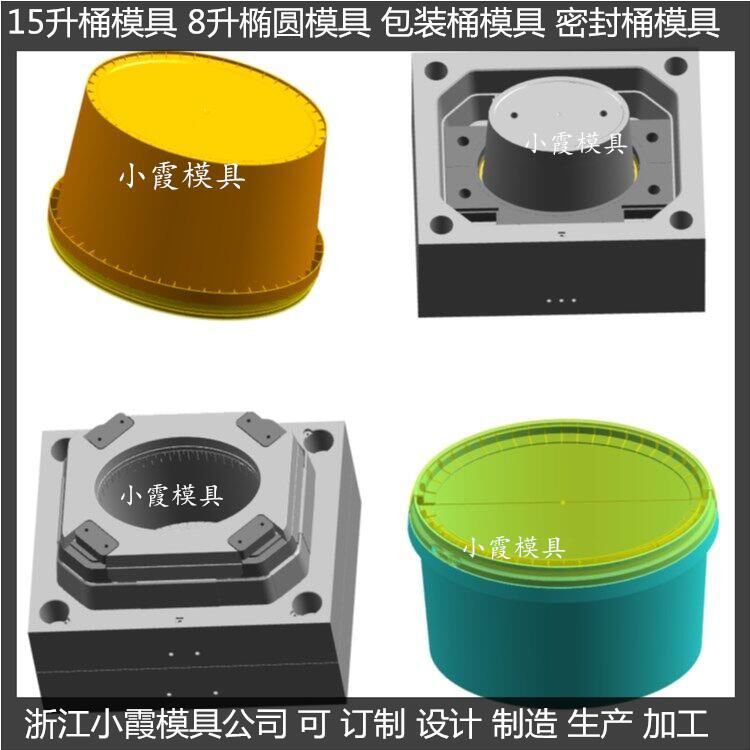

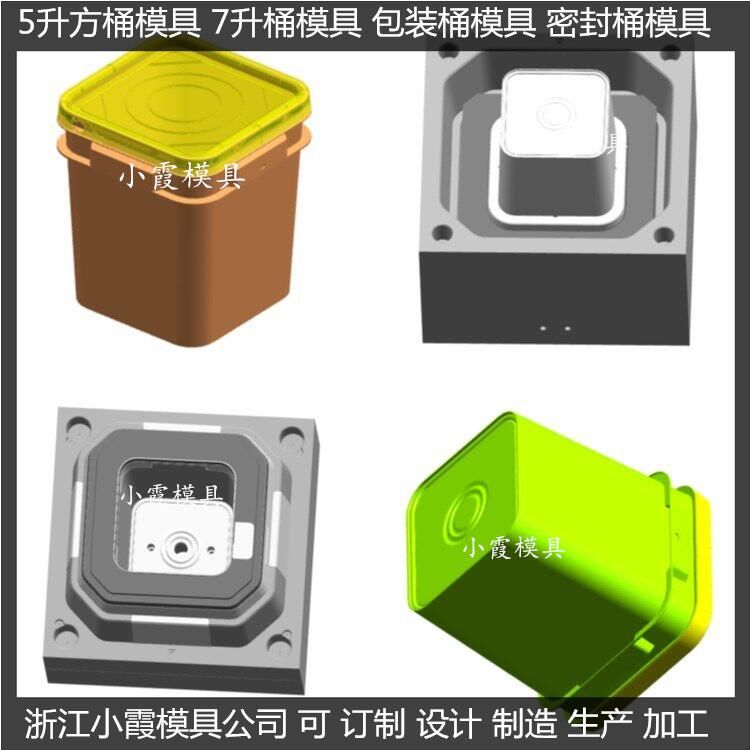

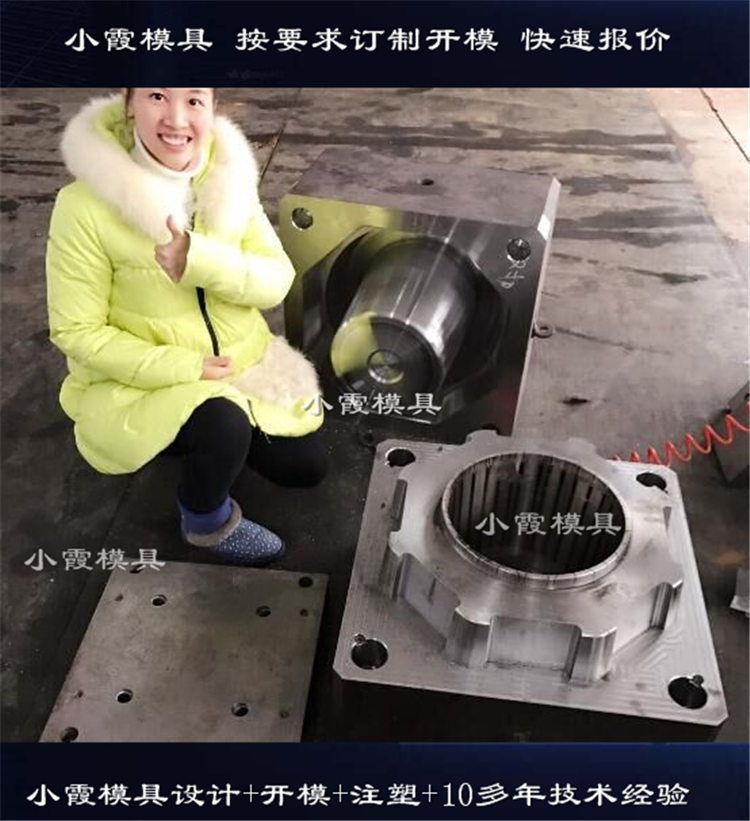

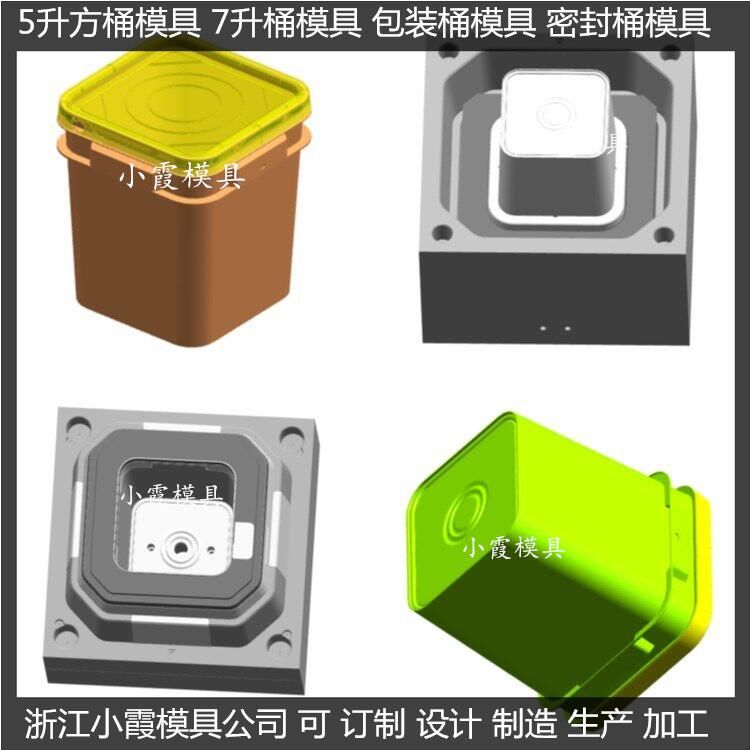

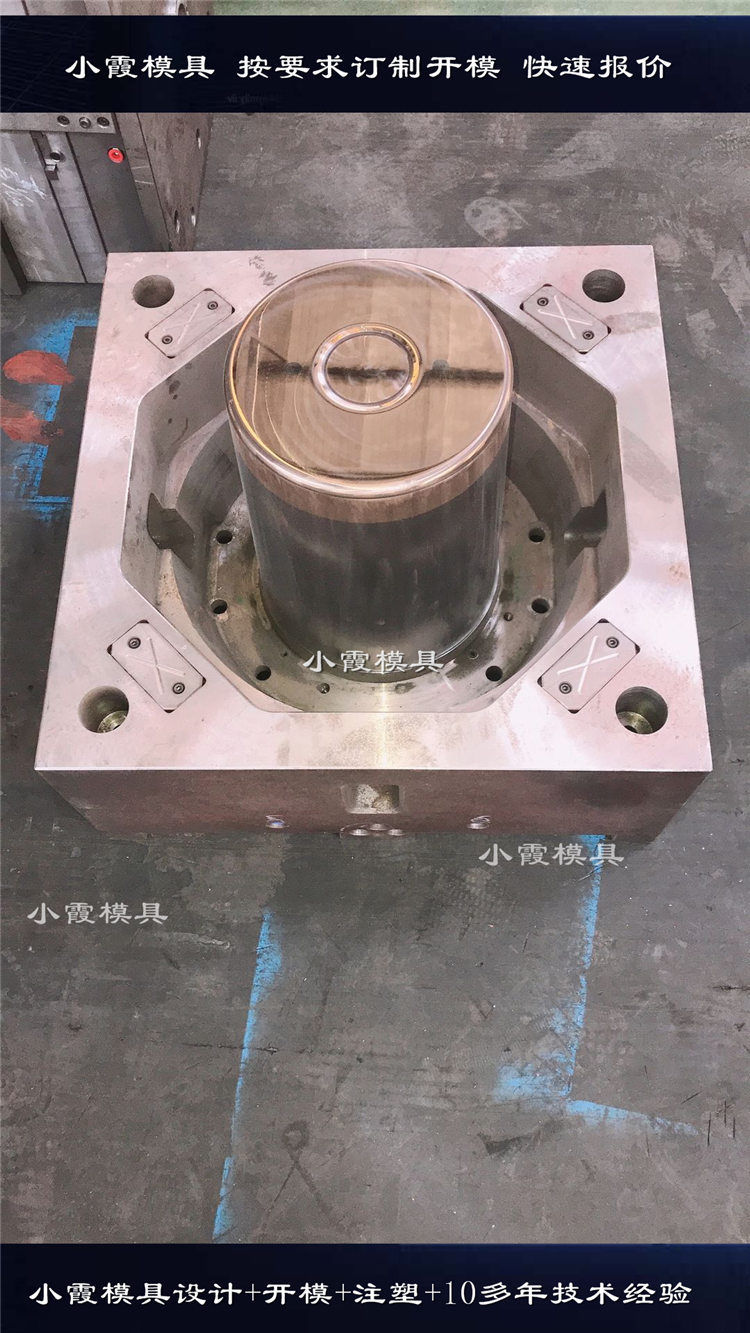

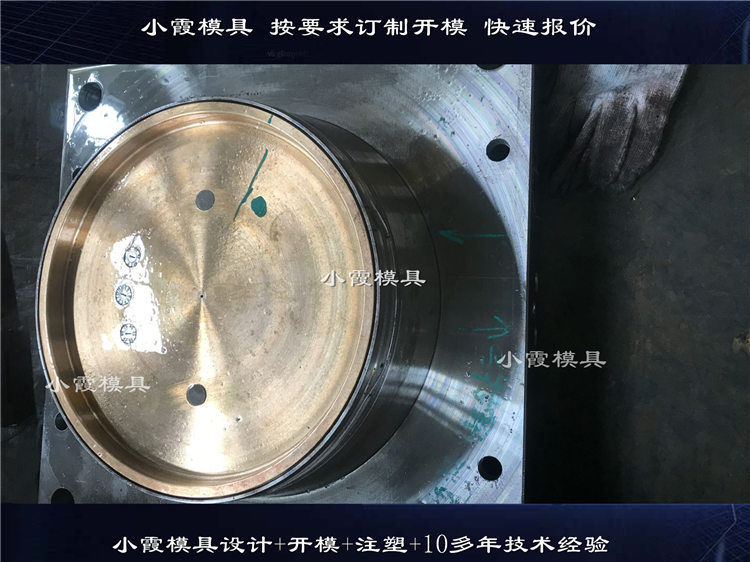

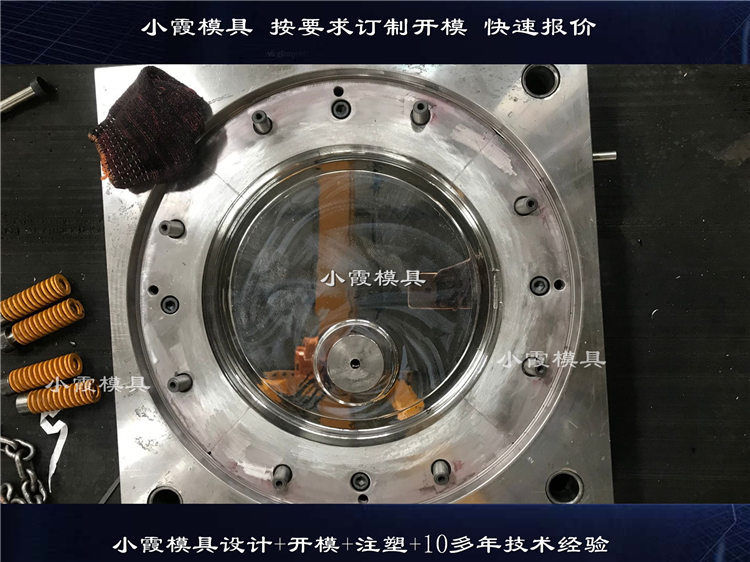

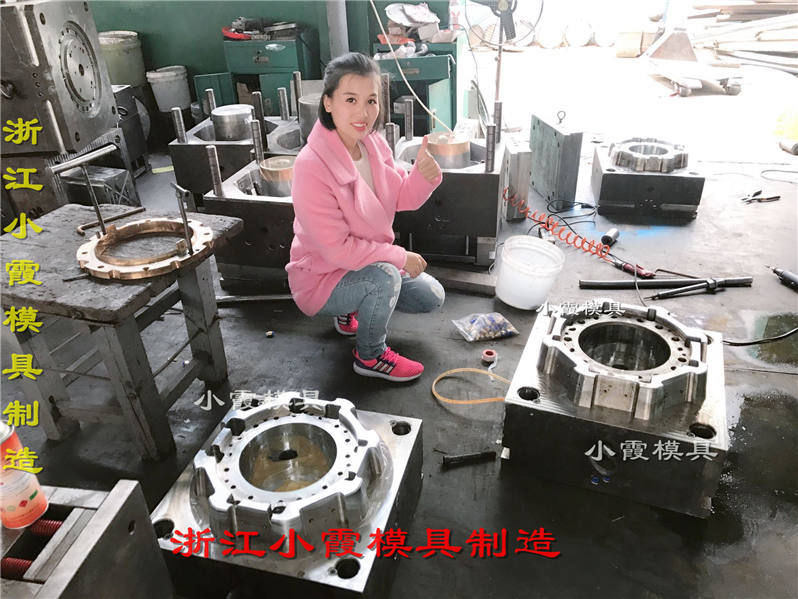

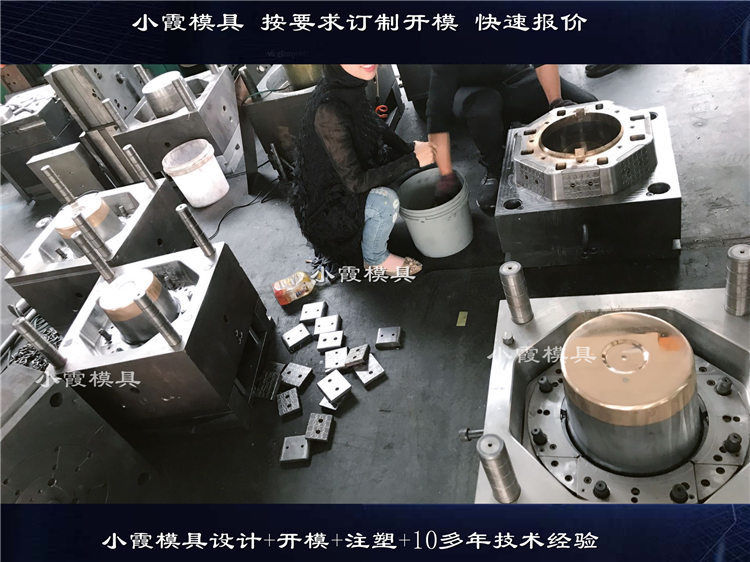

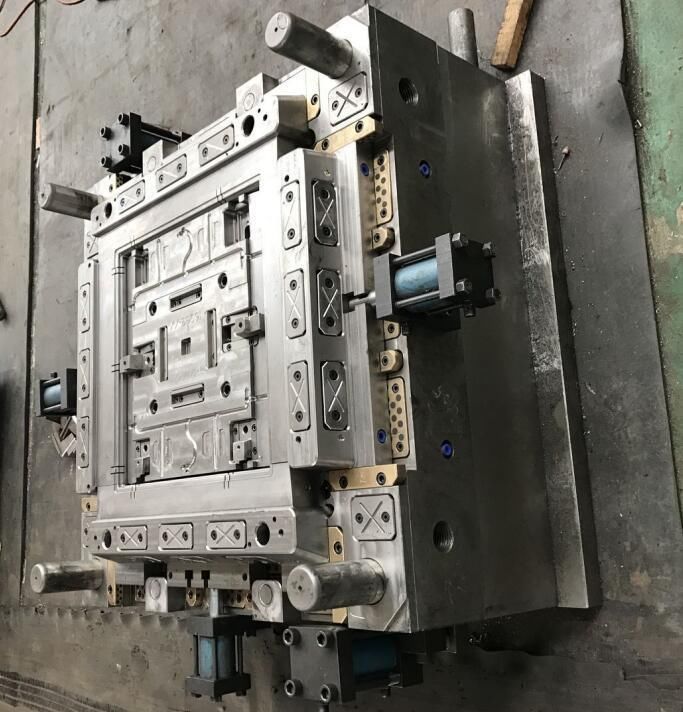

方桶模具方桶塑料模具/精密模具生产线模具厂家

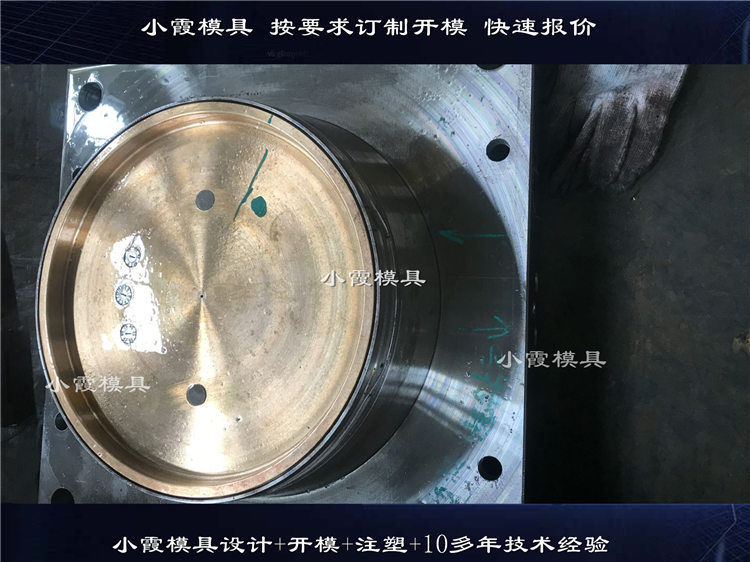

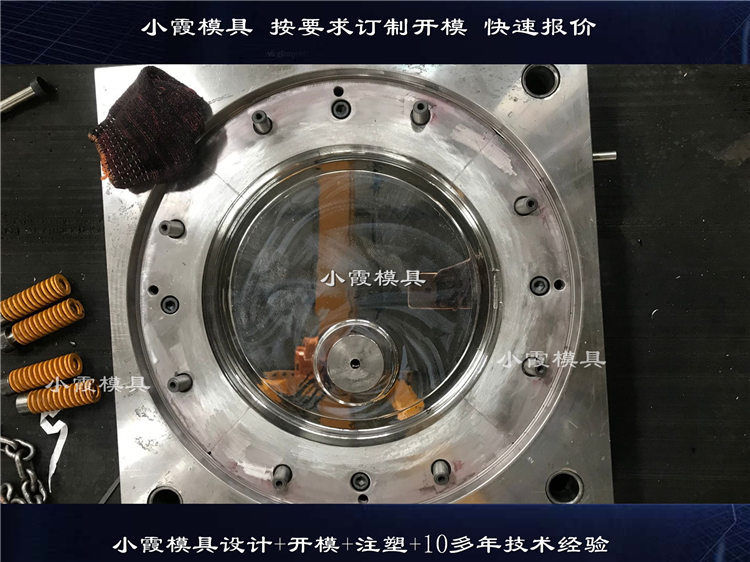

涂料桶模具

亲:提供样品,或者,三维图纸,二维图纸,可以报价开模, 小霞模具有强大设计团队,欢迎您来咨询报价!

产品价格,参数等仅供参考,详情请来电咨询!

如不经协商直接下单,恕不发货!敬请谅解!

因订制产品,按实际情况为你量身定价,谢谢配合!

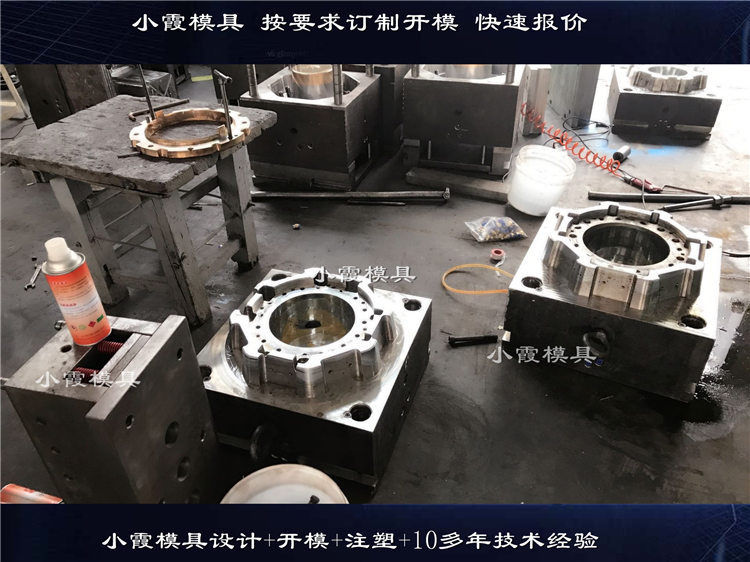

模具材料;P20.718.718H.2738.2316.S136.WAK80.等等多种材料供你选择。模架;45#预硬大于30HRC。

冷却系统;优化设计的循环流水,提高生产效率,降低你的成本中期处理,调质提高硬度。

后期处理;氮化(氮化处理温度低,变形很小)不需要淬火便具有很高的硬度,大于HV850,及耐磨性。

模具寿命;在正常使用不低于50万模次。

运输方式;在模具出运前必须装上锁模片,包装坚固,防锈,物流运输

售后服务;在正常使用情况模具保修1年,保修期间免费维修,在本公司注塑加工的模具,一直免费保修。

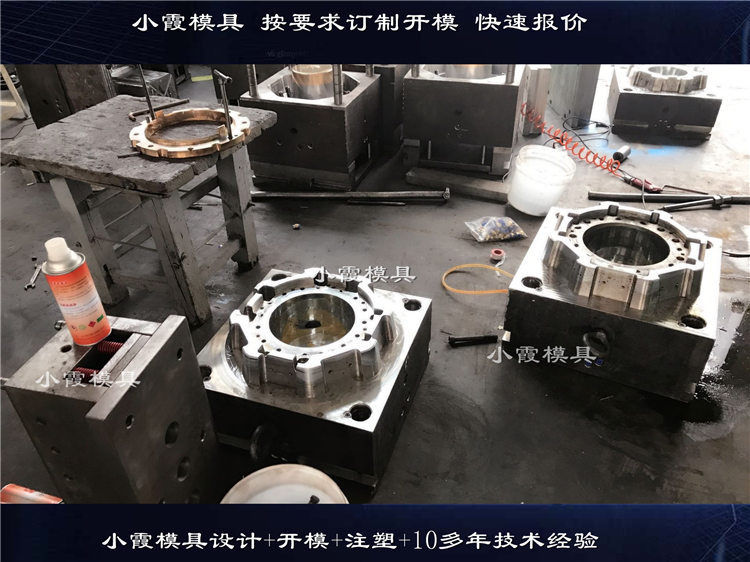

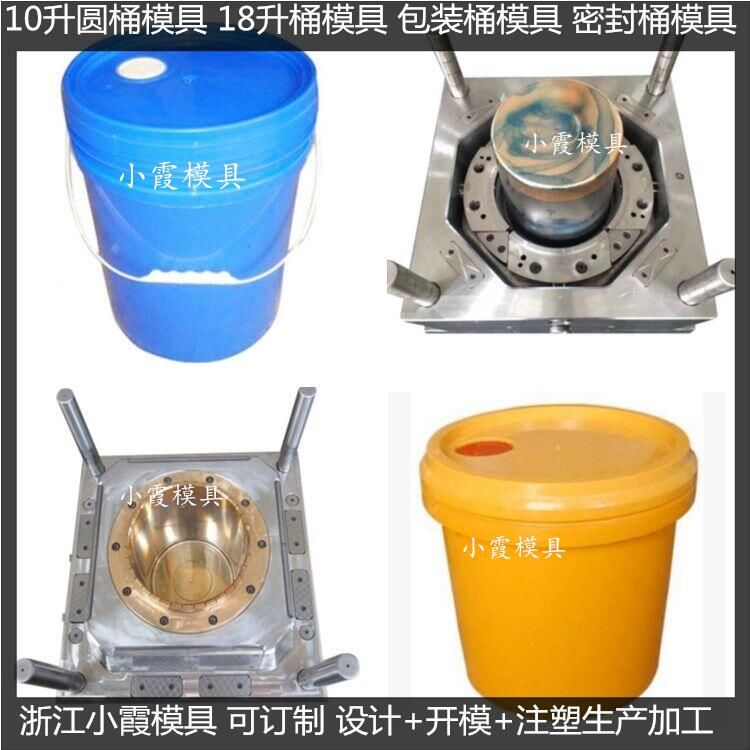

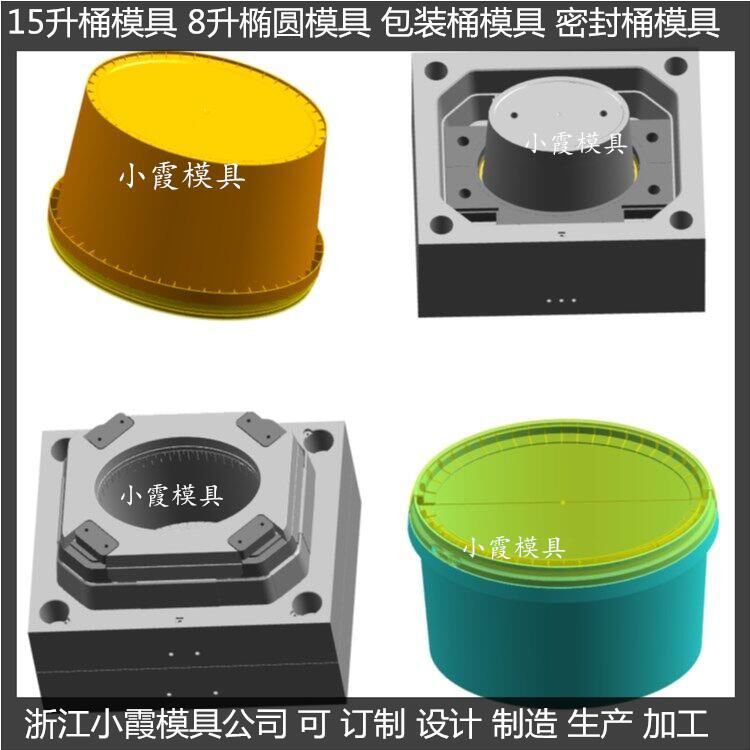

注塑桶模具桶模PP桶模具

桶模PP桶模具PE桶模具

PP桶模具PE桶模具方桶模具

型号: | 按要求定制 |

腔数: | 1出1 |

模架: | LKM, ISM标准,HASCO 或按照客户要求 |

模具材质: | P20, 718H, H13, 2344, 2316, NAK80 |

模具流道系统: | 冷流道/热流道 |

设计软件: | UG; PROE; |

塑料材质: | PP, ABS, HDPE, PC, PVC, PA6, PA66, PET etc. |

模具寿命: | 500,000次- 3,000,000次 |

模具尺寸: | 根据产品设计 |

模具重量: | 根据产品设计 |

样品: | 根据产品设计 |

普通模具交货期: | 35-50天 |

高要求精密模具 | 55-85天 |

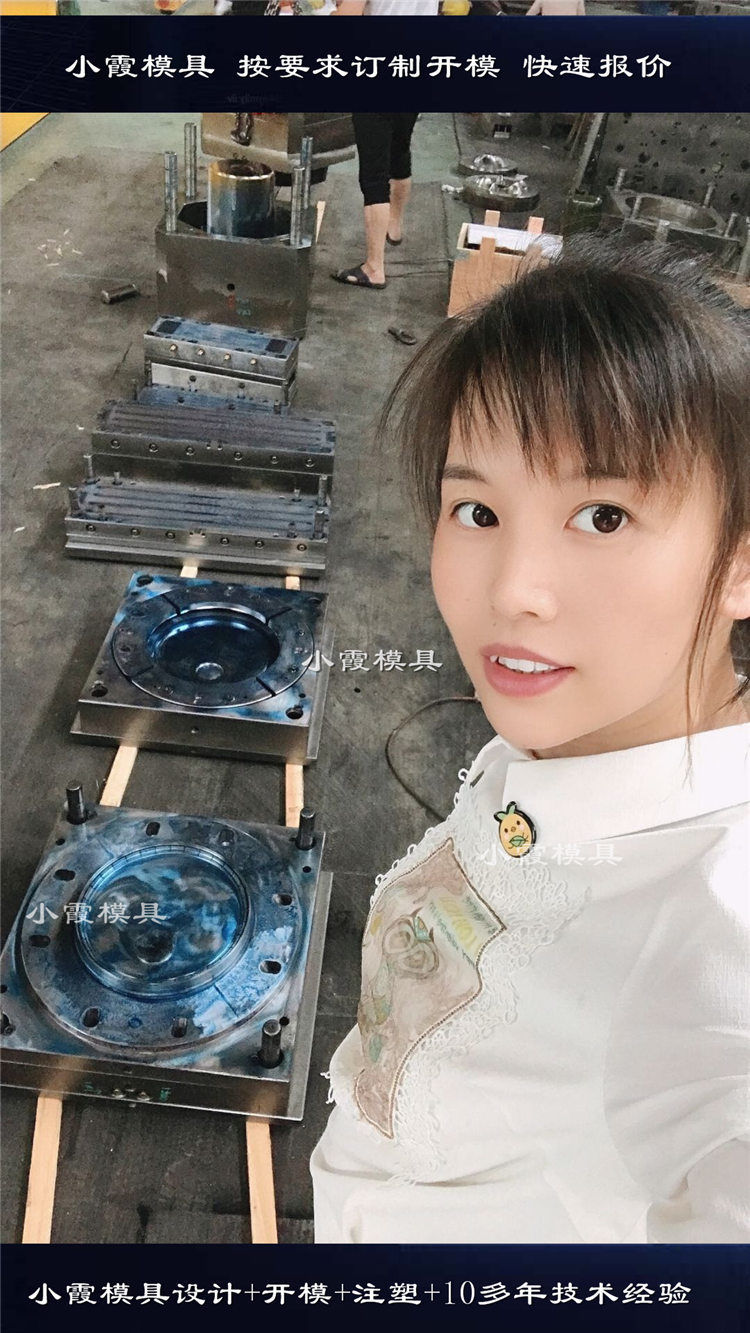

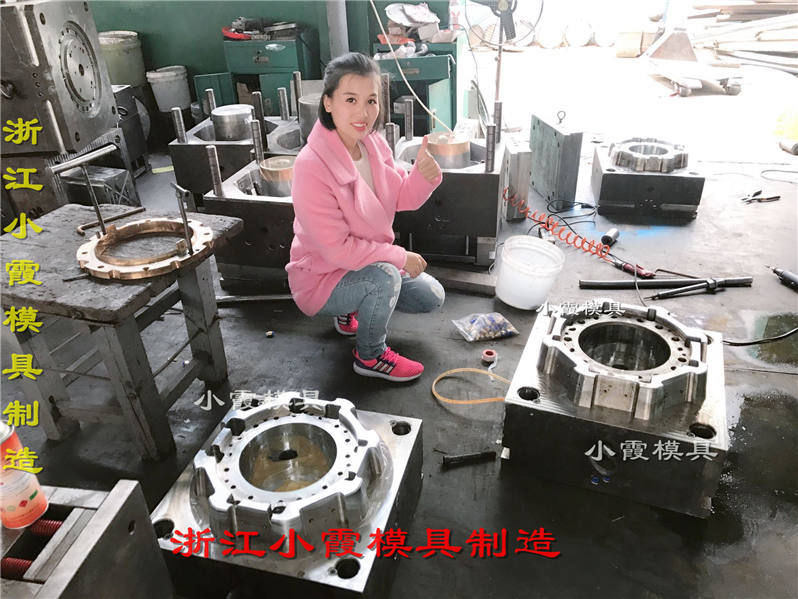

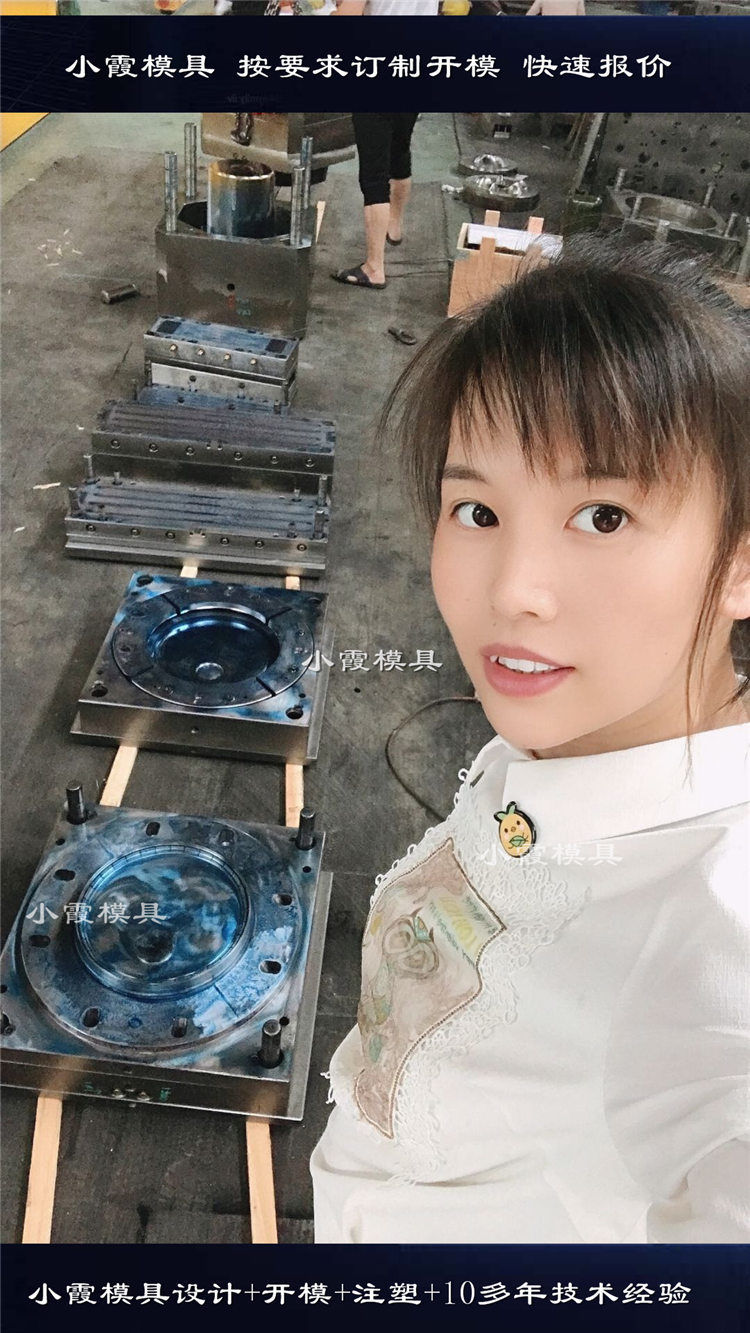

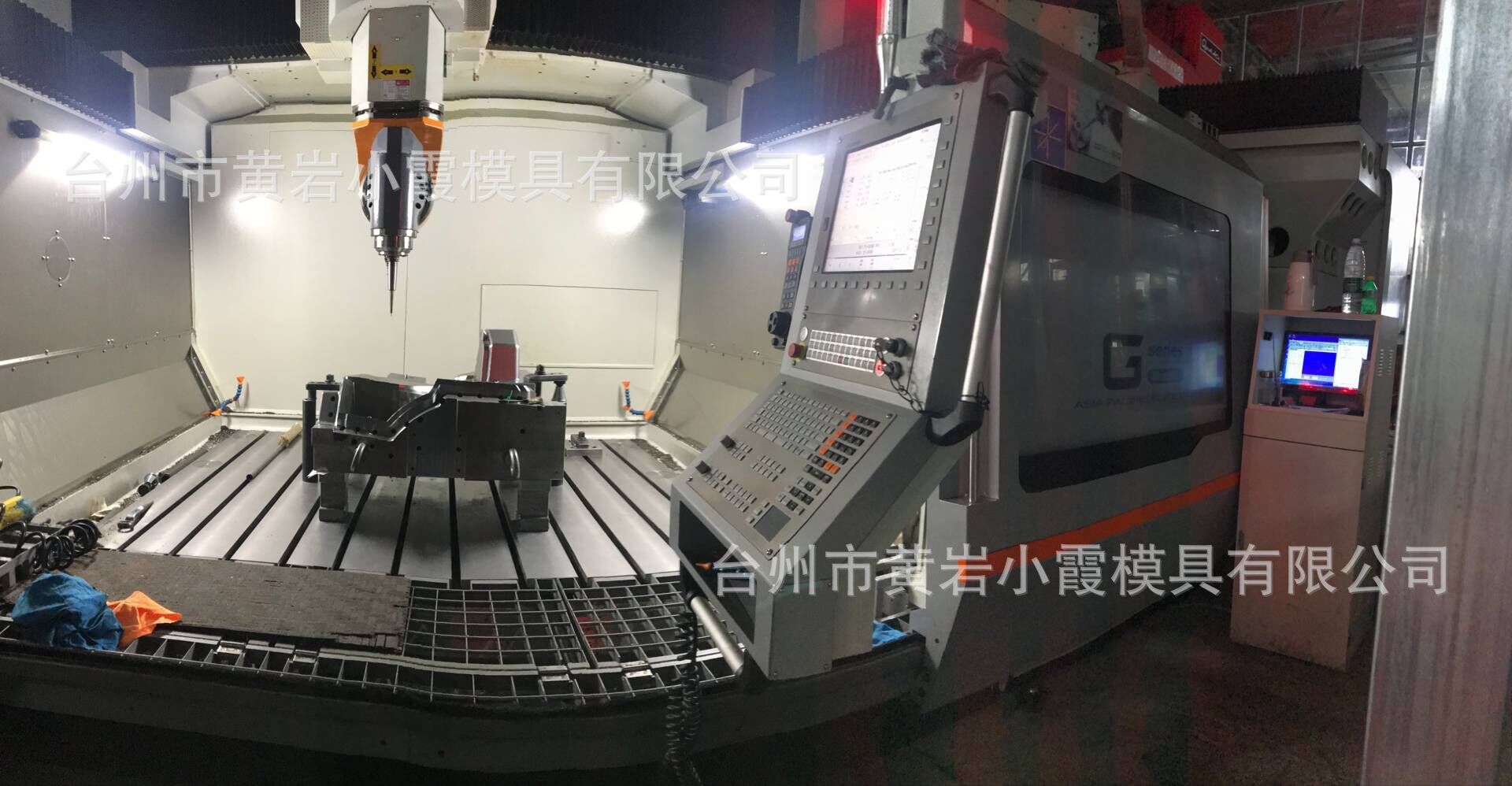

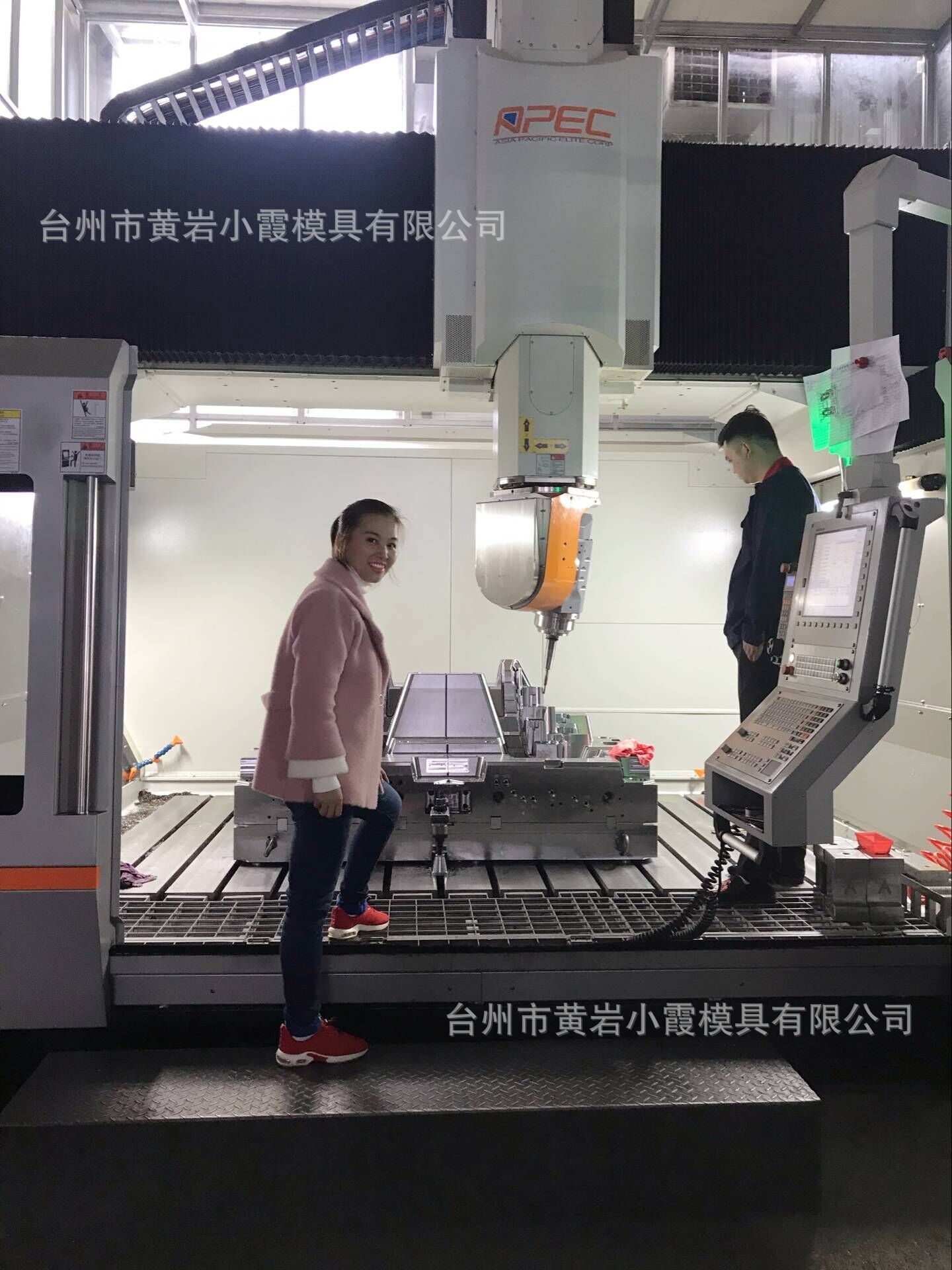

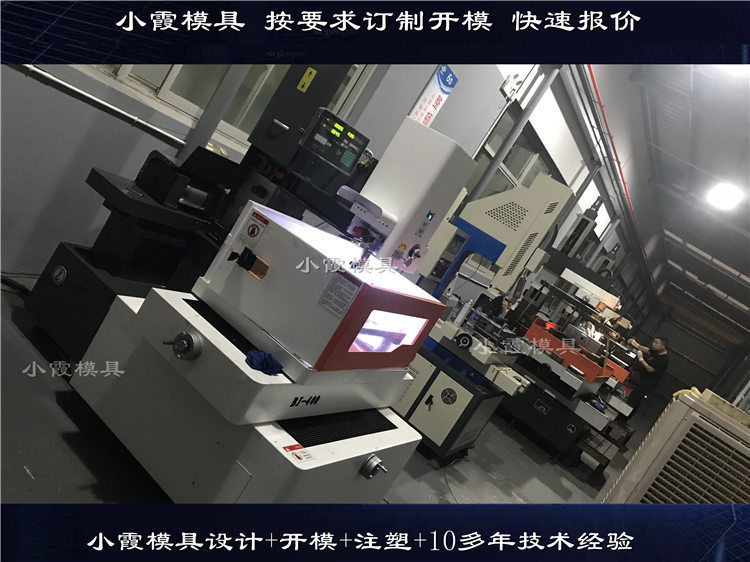

台州市黄岩小霞模具有限公司

小霞模具 浙江小霞模具 台州小霞模具 黄岩小霞模具

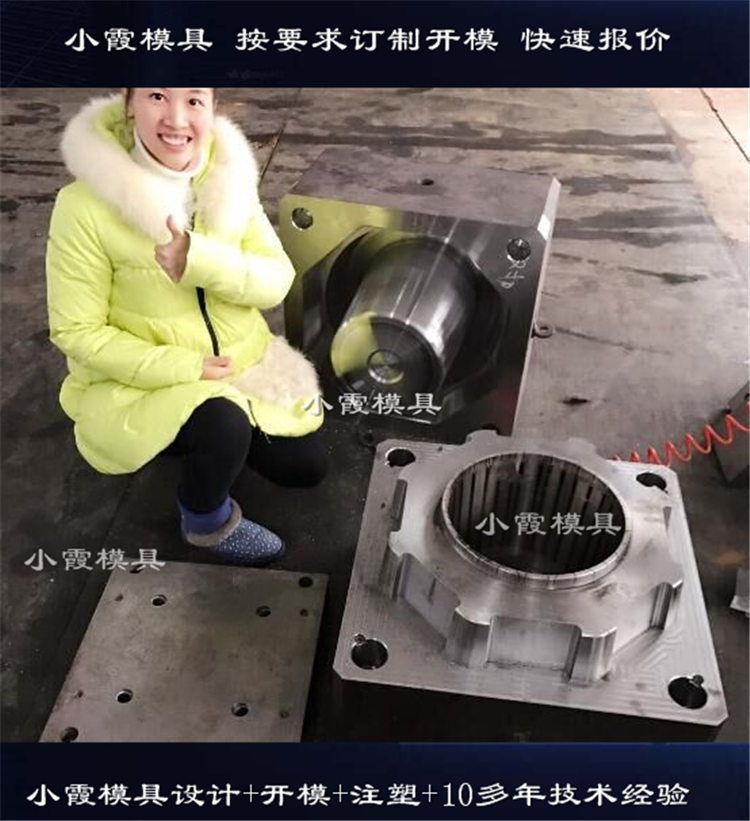

浙江小霞模具公司,主要:模具制造,注塑加工.产品处理:喷漆,烤漆,水转印,电镀,丝印,热转印,在我们公司定做注塑模具可享受大优惠,我为自己 你舍得花钱,我舍得做,一分钱一分货,舍得换新款时尚型。你不舍得花钱,我给你做大气经典型模具,欢迎您来厂订购模具

小霞模具根据客户来图来搞定制,制造塑料模具 生产塑胶模具 做模具 定做注塑模具。

本公司模具款式多样,品质, 合理,有保证。具有安全、卫生、环保,使用寿命长、使用便捷、耐酸碱,耐高温、耐用、轻、美观、强度高等特点。

公司以 的技术, 的产品和周到的服务赢得了广大客户的认可于赞誉,小霞真诚的期待与您友合作和共同发展,能使我们的生活环境更美,让我们共同的家园更环保。

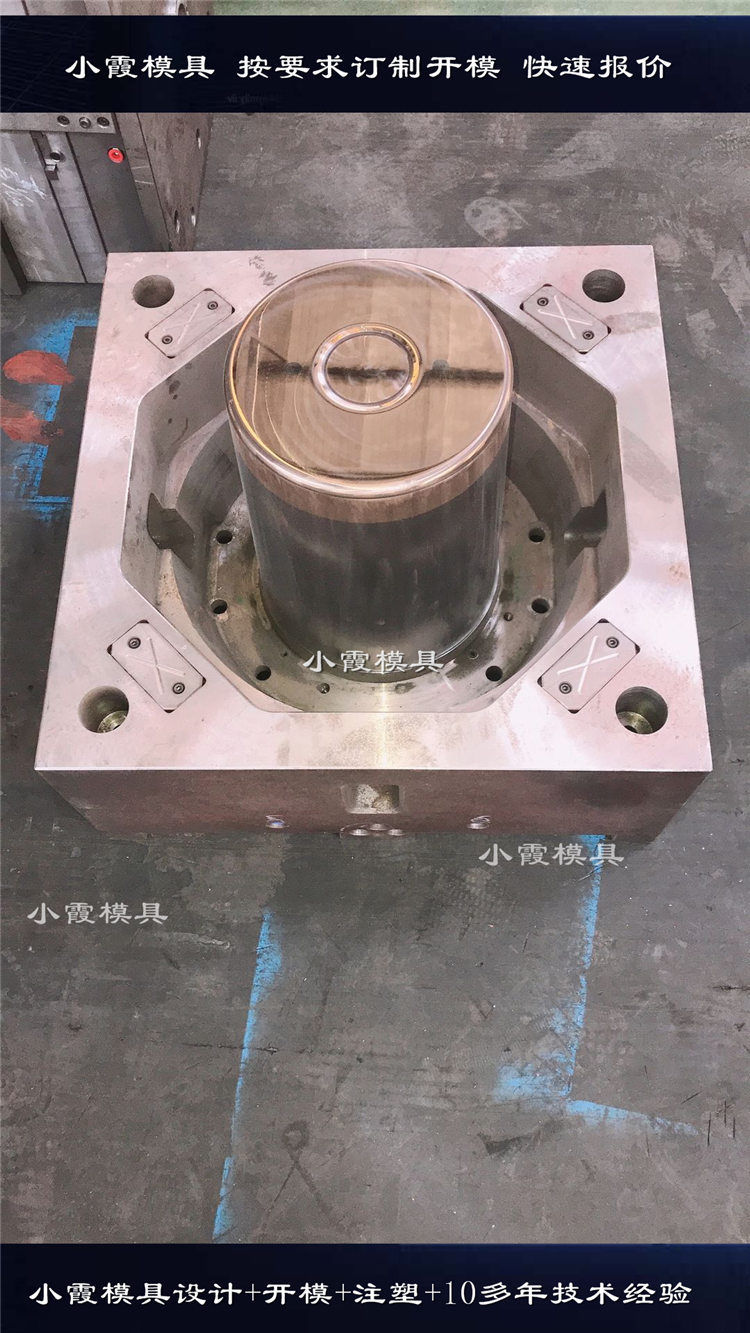

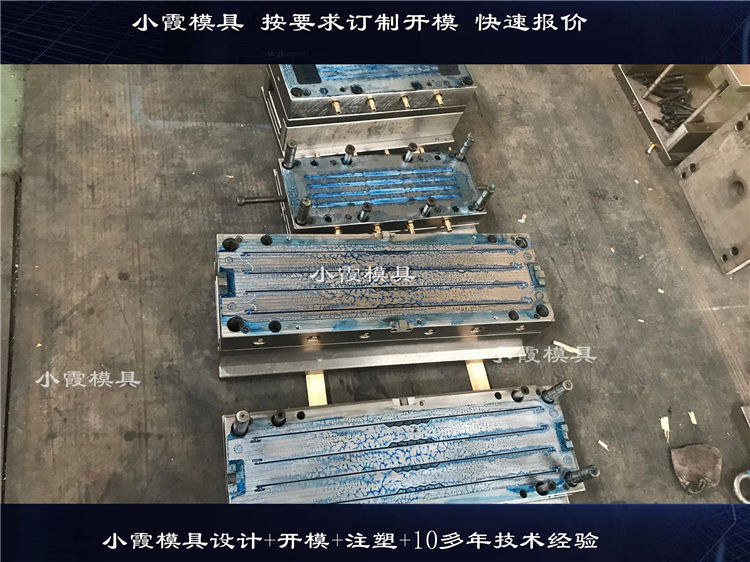

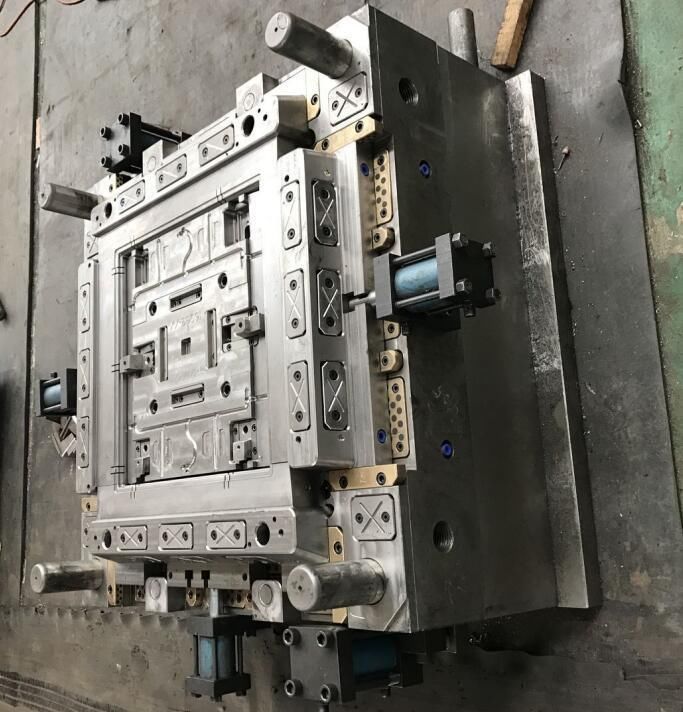

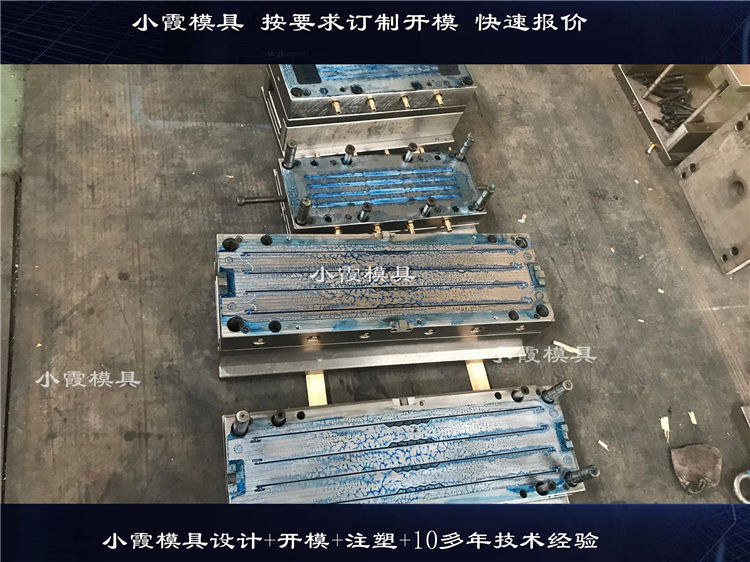

工艺流程 :图纸确定—模具下料---模具粗加工-模具热处理-模具精加工-加工精度检验—模具飞模--试模—试样-修模-合格出运。

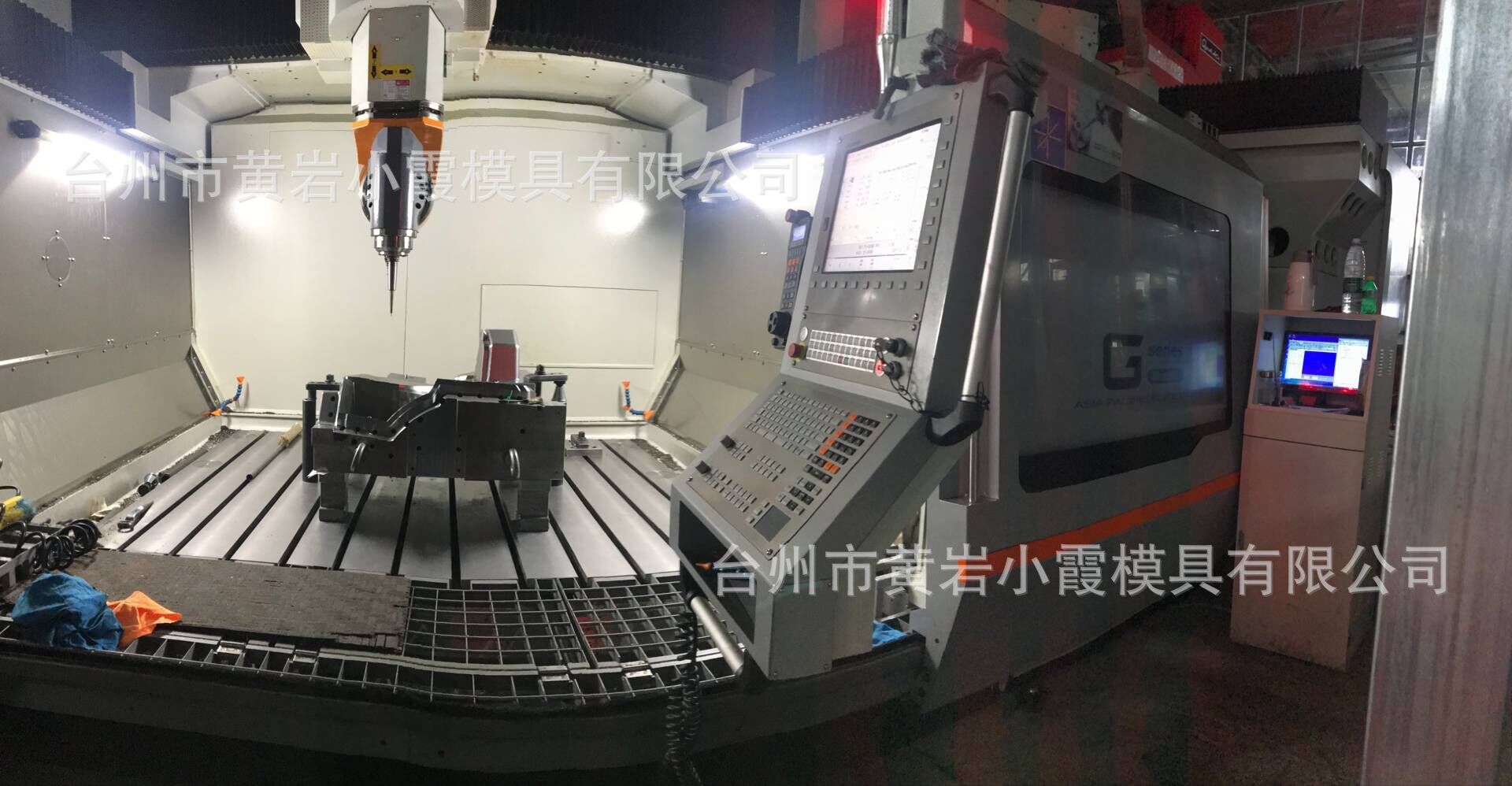

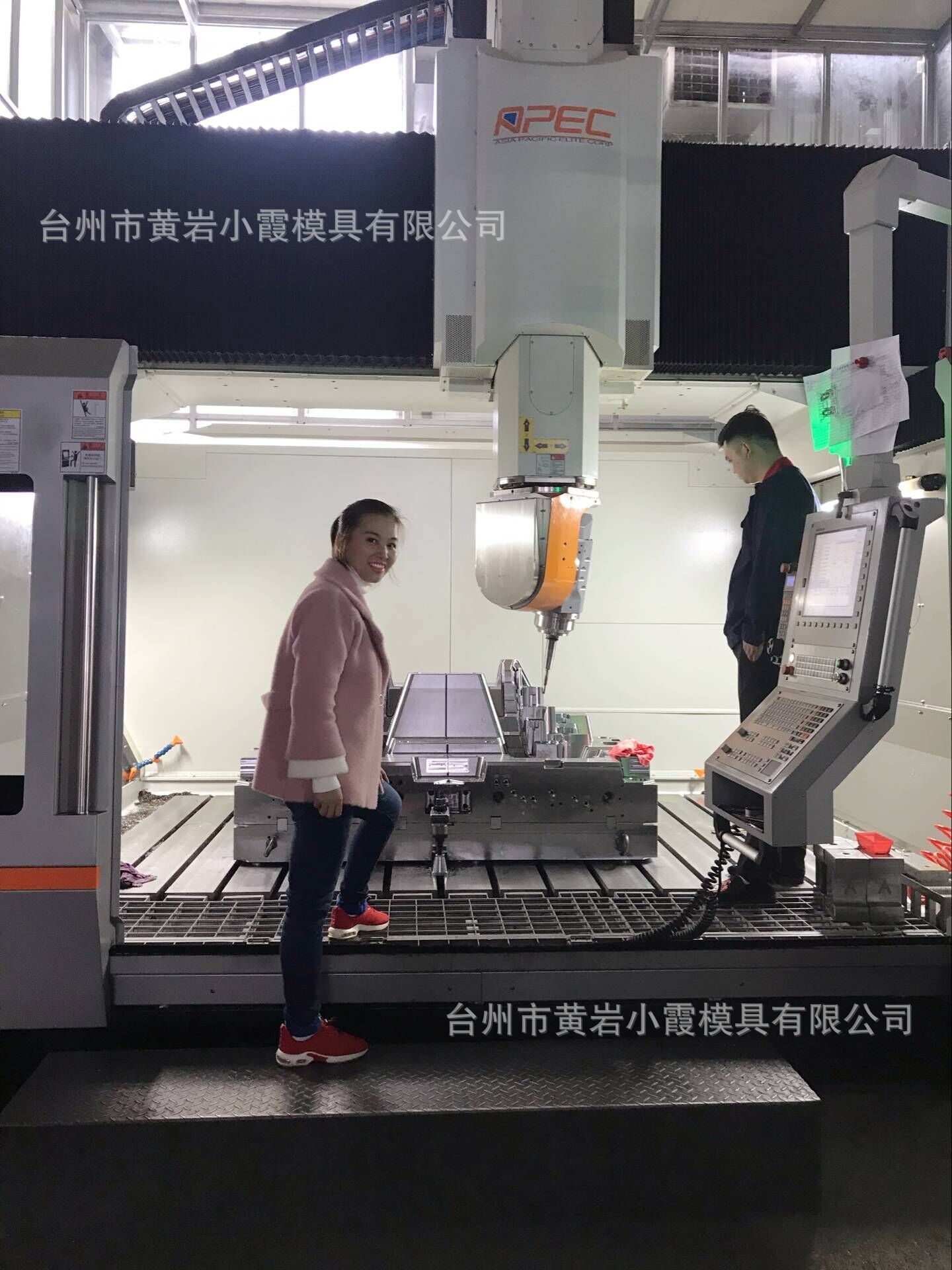

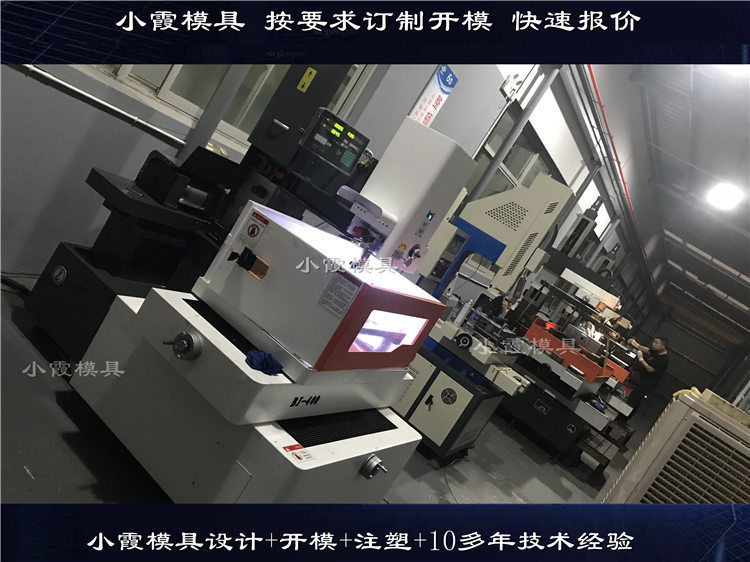

加工设备 :CNC数铣,精雕,电火花,线切割,钻床,磨床,铣床。

加工能力 :模具设计、模具制造及注塑成型加工

模具材料 : 45#,P20, 718, 2738, 2316, NAK80,H13,S136等等多种材料供您选择,模架:45#预硬>30 HRC。

冷却系统 :冷却系统的设计是一项比较繁锁的工作,即要考虑冷却效果及冷却的均匀 ,又要考虑冷却系统对模具整体结构的影响冷却系统的 及尺寸的确定;重点部位如动模或镶件的冷却;侧滑块及侧型芯的冷却;冷却元件的设计及冷却标准元件的。我们公司在模具设计时 分析这些问题,模具采用循环水的方式在模具内部每一个部位流动,降低注塑时的冷却时间, 产品的生产效率,大大降低生产成本。优化设计的循环, 生产效率,降低您的成本。

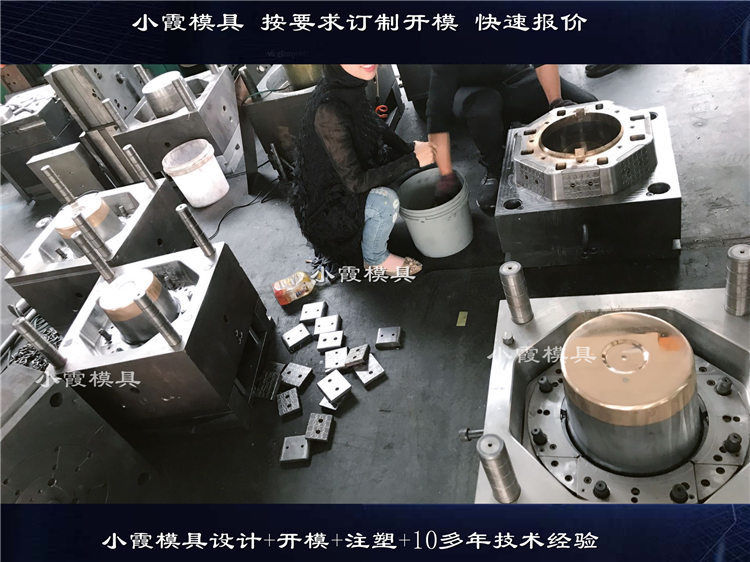

中期处理 :调质, 硬度。

后期处理 :处理温度低,变形很小,不再需要进行淬火便具有很高的 硬度(大于HV850)及耐磨 )

模具寿命 : P20正常使用不低于100万模次

运输方式 :在模具出运前必须装上锁模片,包装坚固、防锈,物流运输

1对产品成型工艺、模具结构及制作工艺进行分析。保证模具寿命高达100万次以上。

2.必须设计完整的模具结构及加工零件,并提出装配要求及注塑工艺要求。

3.造成塑件外观缺陷(如收缩等)或模具结构问题(如分型面设置、浇口设置、模具寿命无法保证等问题)。

4.模具外观:模具外观必须保证无锈迹、无撞痕、无残缺勤等模块缺陷。

5.模具运输:模具运输必须装上锁模片,包装坚固、防锈。

6.模具资料:在模具交货的同时,必须提供一整套模具易损件和维修保养参考资料.

小霞模具有强大设计团队可接受:提供样品,或者,三维图纸,二维图纸,可以报价开模,欢迎您来咨询报价!

浙江小霞实力强大,能:模具制造,产品加工,产品 处理,产品安装,小霞模具能有一系列生产制造服务!

温馨提示:

浙江小霞模具欢迎你来公司指导定做模具。制造塑料注塑模具。

Plastic mold 2023-02-01工号: 88 Y

","gnid":"9ce94219f1c6f47dd","img_data":[{"flag":2,"img":[{"desc":"","height":"750","title":"","url":"https://p0.ssl.img.360kuai.com/t010387af342efe476a.jpg","width":"750"},{"desc":"","height":"750","title":"","url":"https://p0.ssl.img.360kuai.com/t01fd7ba19ac61aa452.jpg","width":"750"},{"desc":"","height":"750","title":"","url":"https://p0.ssl.img.360kuai.com/t0162b4c288e5c6f405.jpg","width":"750"},{"desc":"","height":"1333","title":"","url":"https://p0.ssl.img.360kuai.com/t0198afa59740626612.jpg","width":"750"},{"desc":"","height":"1333","title":"","url":"https://p0.ssl.img.360kuai.com/t01b9cacbc3bd501fe4.jpg","width":"750"},{"desc":"","height":"562","title":"","url":"https://p0.ssl.img.360kuai.com/t019b8ea91020e0dc5b.jpg","width":"750"},{"desc":"","height":"562","title":"","url":"https://p0.ssl.img.360kuai.com/t019eea78c2887cc8ee.jpg","width":"750"},{"desc":"","height":"1333","title":"","url":"https://p0.ssl.img.360kuai.com/t01af43e4c99c4b8ae9.jpg","width":"750"},{"desc":"","height":"1333","title":"","url":"https://p0.ssl.img.360kuai.com/t01b8bd86108713fc5b.jpg","width":"750"},{"desc":"","height":"1000","title":"","url":"https://p0.ssl.img.360kuai.com/t010fb15ed4c32ba195.jpg","width":"750"},{"desc":"","height":"1333","title":"","url":"https://p0.ssl.img.360kuai.com/t018f8d0efe33261761.jpg","width":"750"},{"desc":"","height":"1102","title":"","url":"https://p0.ssl.img.360kuai.com/t01a8a470411490d705.jpg","width":"620"},{"desc":"","height":"750","title":"","url":"https://p0.ssl.img.360kuai.com/t01f176e1d21fad2ede.jpg","width":"1000"},{"desc":"","height":"599","title":"","url":"https://p0.ssl.img.360kuai.com/t01124317fc60f08246.jpg","width":"798"},{"desc":"","height":"821","title":"","url":"https://p0.ssl.img.360kuai.com/t0103025515d19c2d6e.jpg","width":"750"},{"desc":"","height":"1333","title":"","url":"https://p0.ssl.img.360kuai.com/t01d75c91901297b143.jpg","width":"750"},{"desc":"","height":"562","title":"","url":"https://p0.ssl.img.360kuai.com/t01ea99a78333b21676.jpg","width":"750"},{"desc":"","height":"1000","title":"","url":"https://p0.ssl.img.360kuai.com/t01ee9c02fda7225898.jpg","width":"750"},{"desc":"","height":"562","title":"","url":"https://p0.ssl.img.360kuai.com/t0171cd514b344bc6e8.jpg","width":"750"},{"desc":"","height":"562","title":"","url":"https://p0.ssl.img.360kuai.com/t01a418f34094ce5b5a.jpg","width":"750"},{"desc":"","height":"562","title":"","url":"https://p0.ssl.img.360kuai.com/t011795844ba2a9fa1a.jpg","width":"750"},{"desc":"","height":"647","title":"","url":"https://p0.ssl.img.360kuai.com/t019a29f31150093255.jpg","width":"1920"},{"desc":"","height":"852","title":"","url":"https://p0.ssl.img.360kuai.com/t01a7fe9c7cf39b06dd.jpg","width":"1136"},{"desc":"","height":"1440","title":"","url":"https://p0.ssl.img.360kuai.com/t016f084ff8cba4a9bb.jpg","width":"1920"},{"desc":"","height":"1440","title":"","url":"https://p0.ssl.img.360kuai.com/t018fc3ee76ac63bfc8.jpg","width":"1920"},{"desc":"","height":"1919","title":"","url":"https://p0.ssl.img.360kuai.com/t0138093e6cc9d4f845.jpg","width":"1440"},{"desc":"","height":"1440","title":"","url":"https://p0.ssl.img.360kuai.com/t0168d9a8d6d69c3a64.jpg","width":"1920"},{"desc":"","height":"1920","title":"","url":"https://p0.ssl.img.360kuai.com/t010e07ceb9a1b7b414.jpg","width":"886"},{"desc":"","height":"1440","title":"","url":"https://p0.ssl.img.360kuai.com/t01562b31f662c81cef.jpg","width":"1920"},{"desc":"","height":"998","title":"","url":"https://p0.ssl.img.360kuai.com/t01b6856b0537173763.jpg","width":"1920"},{"desc":"","height":"1920","title":"","url":"https://p0.ssl.img.360kuai.com/t0126a2ac66003772ad.jpg","width":"1440"},{"desc":"","height":"714","title":"","url":"https://p0.ssl.img.360kuai.com/t0169293f20c0e543f3.jpg","width":"1089"},{"desc":"","height":"562","title":"","url":"https://p0.ssl.img.360kuai.com/t010cc9855606ab3ecd.jpg","width":"750"},{"desc":"","height":"562","title":"","url":"https://p0.ssl.img.360kuai.com/t0198cd509eb3d5e3ad.jpg","width":"750"},{"desc":"","height":"712","title":"","url":"https://p0.ssl.img.360kuai.com/t019c43edbd1c0dec35.jpg","width":"683"},{"desc":"","height":"1280","title":"","url":"https://p0.ssl.img.360kuai.com/t01cc3017655f2d7e40.jpg","width":"960"},{"desc":"","height":"960","title":"","url":"https://p0.ssl.img.360kuai.com/t01772b499c411d069e.jpg","width":"1280"},{"desc":"","height":"960","title":"","url":"https://p0.ssl.img.360kuai.com/t01ae342d8451e44414.jpg","width":"1280"}]}],"original":0,"pat":"art_src_1,fts0,sts0","powerby":"hbase","pub_time":1689738680000,"pure":"","rawurl":"http://zm.news.so.com/c27017399e62eef6b741c1c9461ecc68","redirect":0,"rptid":"3375abd88e80d9d9","rss_ext":[],"s":"t","src":"小霞模具","tag":[],"title":"方桶模具方桶塑料模具/精密模具生产线模具厂家

澹陈柿2910塑料模具打产品有时有飞边有时没有怎么回事 -

骆郎荀19696667141 ______ 可能是模具强度不够,射胶时变形了,也可能是模面没及时清理有异物,有可能是模具定位有间隙,或还有其它一些异常.反正是成型时公母模间隙超过了塑料的溢边值.需逐一分析排除.昆山塑德模具设计,模具设计专家.1391321053

澹陈柿2910请教前辈们飞模(FIT)是什么意思? -

骆郎荀19696667141 ______ 飞模是广东,香港佬的一种说法,是方言来的,已经流行于整个模具制造行业,书上根本没这个词.

澹陈柿2910塑胶模具如果不能用打磨机配模,怎么实现? -

骆郎荀19696667141 ______ 飞模=合模,零飞模=零合模?什么意思?注塑模具在装配时,免不了要修修配配的.想要一点也不用修配,就能够直接组装在一起试模,除非是那种公差比较大的模具才可以做到.注塑模具在组装时,如果能够使用打磨机配模,说明需要修配的余量还是比较大.如果不能用打磨机配模,可以使用手摇磨自己去磨多余的余量.剩余的余量可以使用油石、超声波抛光机打磨去掉多余的余量,最后再抛光即可.

澹陈柿2910塑胶模具飞模目的是为了什么? -

骆郎荀19696667141 ______ 为了测试风的阻力

澹陈柿2910模具飞模精确到什么数据 -

骆郎荀19696667141 ______ 飞模就是配模或者标模. CNC EDM,等加工完成后都会有工差,需要手工完成就叫飞模,省模是指把模具抛光有利于脱模,或有利于外观好看. 飞模要使用到红丹,类似印泥,两面贴合会有红色印记,在封胶位面的地方如果没有印记,就标示这里有问题,就需要打磨.

澹陈柿2910飞模工艺的施工实例 -

骆郎荀19696667141 ______ 现以太平洋大饭店为例.上海太平洋大饭店工程建筑面积为68300m2,地下2 层,地上28 层(图7).结构造型以曲线为主,结构形式为框架—剪力墙体系.外形的长度比为5:1,如采用滑模施工很难保证几何尺寸和质量要求,加之滑模工艺连...

澹陈柿2910塑胶模具制作有几个工序 -

骆郎荀19696667141 ______ 首先是根据据产品设计模具,模具设计好后,如果是注塑模具一般要进行模流分析,确定流道等.根据模具图纸定料,下料,粗加工,精加工,组装,带有水冷系统的模具要试压,防止漏水,然后试模,再根据试模情况进行改模,直到模具符合使用要求

澹陈柿2910模具飞模的具体操作方法? -

骆郎荀19696667141 ______ 先把模型画出来然后加工 哈哈

澹陈柿2910塑胶模具的工艺性

骆郎荀19696667141 ______ 模具加工流程 开料:前模料、后模模料、镶件料、行位料、斜顶料; 开框:前模模框、后模模框; 开粗:前模模腔开粗、后模模腔开粗、分模线开粗; 铜公:前模铜公、后模铜公、分模线清角铜公; 线切割:镶件分模线、铜公、斜顶枕位; ...

澹陈柿2910注塑模具怎么调模 -

骆郎荀19696667141 ______ 根据试模的情况对模具存在的问题做针对性的修配、调整.比如:如果注塑件毛刺大,则有可能是模具配合的间隙大,贴合的不严实,或者注塑件缺料,或者有气泡,则有可能是模具进料口过小,或者排气槽太少.根据注塑件出现的问题做针对性的修配.有些问题可能模具本身的问题,有些问题则是注塑机各种参数调整不到位的问题.具体的问题具体分析,做出相应的调整.