扩孔的方法有哪两种

作者:redbreave1

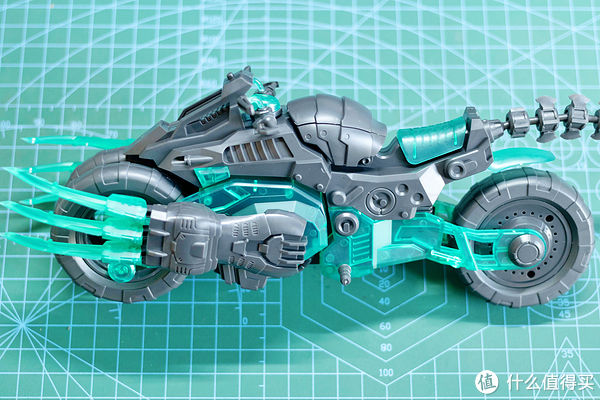

周末又来清理堆积了,这次拼的是之前堆积的摩托车,这款产品性价比还是可以的,体积也较大,是之前一款机娘的配件包的简化板,话说这个模型厂家真的很适合做机械产品不适合做机娘产品,毕竟上一款差评到130+包邮的程度,可能更低,这次把好评的摩托单买算是平摊成本了

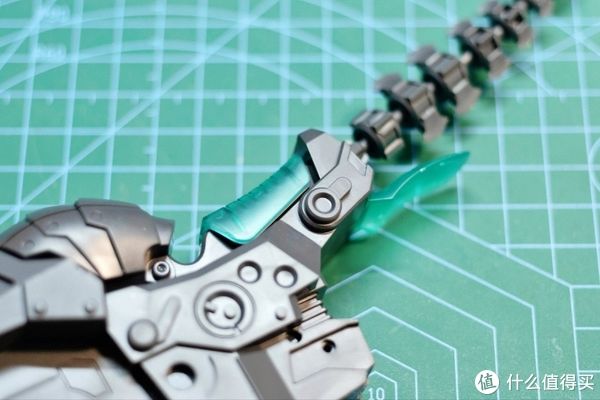

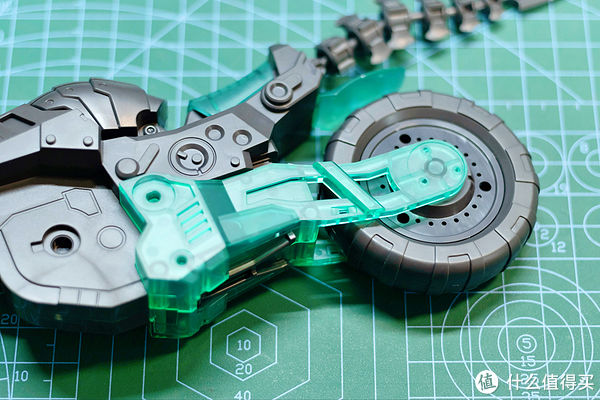

突出的是大爪子的设计,特效件很锐利扎手,而且可以拿掉换普通模式

主要是经典的尾巴设计有点生物的感觉

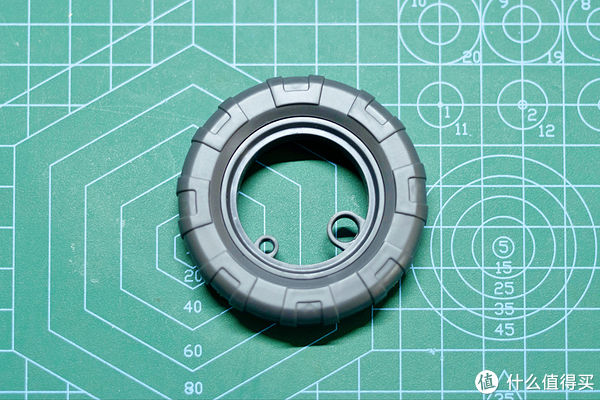

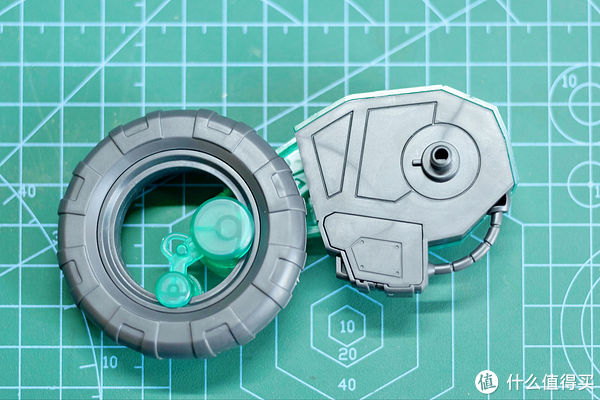

前轮有两个轮胎,就算没有支架都能平稳站立

没想到吧连挡泥板都做了,而且还是特效件

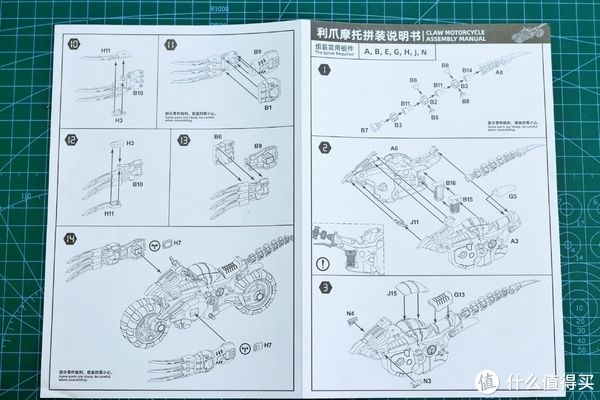

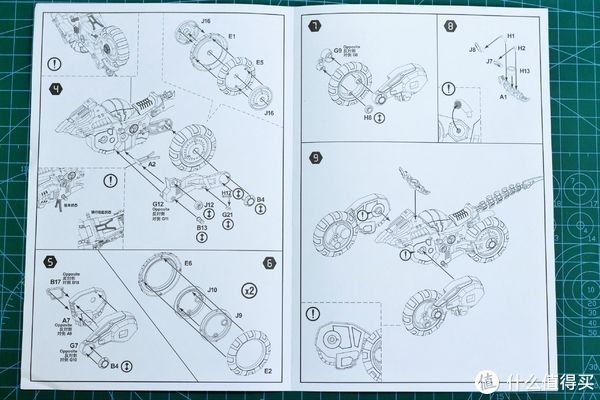

说明书内容很少四折页,安装加打磨时间一个半小时

实际拼装说明书没有错误,但也没有关键提示,比如说轮胎和反光镜安装方法

尾巴为多段可动,设计比较巧妙,但是骨骼零件容易掉,这里502加固过

车身结构左右合,大块零件组合,特别简单,但细节不足,这也是诟病最大的地方

车灯是特效件,安装了拿不下来,别安装错了

座椅也是特效件,安装丝滑,不用修件

这部分也是左右合,没有设计嵌套结构,显得会有点素

细节到位,但是安装的时候要对位,不然会影响美观,这个说明书没说,这里也是安装后用拆件器重新安装后的样子

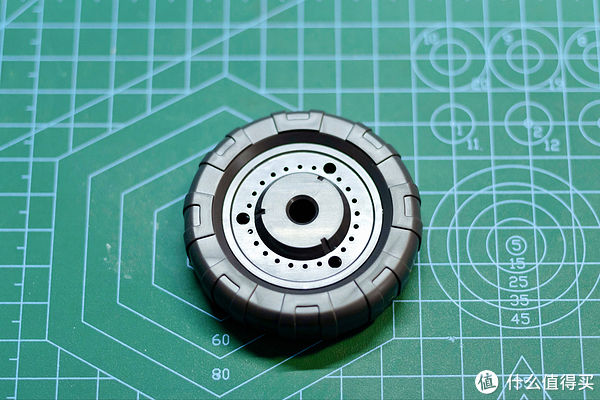

结构和后轮有区别,内外圈是可以滑动的

这里也是用了特效件,零件细节还是比较锐利的

看不见的地方也有刻线细节,就是比较粗

有一定的可动,但是可动不对,细节还是丰富的,但是结构是简单的左右合

这里是最要吐槽的地方,做工问题零件安装不上,最终502加固

完成图还是好看的,整个过程除了车把没有扩孔,拼装丝滑,细节到位

由于是沿用旧版模型一堆废件,这个也会平摊到成本,不然价格可以更低

最适合的场景是搭配1:144模型,比如hg高达,这款是高高超越全球,十几块钱送一堆武器,性价比也不错,那么本次的拼装体验就到这里,感谢大家地观看,也请一键三连

","gnid":"9082d10e65f6a1825","img_data":[{"flag":2,"img":[{"desc":"","height":"400","title":"","url":"https://p0.ssl.img.360kuai.com/t0160095f0d38674756.jpg","width":"600"},{"desc":"","height":"400","title":"","url":"https://p0.ssl.img.360kuai.com/t01c230e4b584957b22.jpg","width":"600"},{"desc":"","height":"400","title":"","url":"https://p0.ssl.img.360kuai.com/t018780125334e722be.jpg","width":"600"},{"desc":"","height":"400","title":"","url":"https://p0.ssl.img.360kuai.com/t01fc7706724fc05742.jpg","width":"600"},{"desc":"","height":"400","title":"","url":"https://p0.ssl.img.360kuai.com/t01ca753866dddbede5.jpg","width":"600"},{"desc":"","height":"400","title":"","url":"https://p0.ssl.img.360kuai.com/t01a16cf317753b01fc.jpg","width":"600"},{"desc":"","height":"400","title":"","url":"https://p0.ssl.img.360kuai.com/t01661a2685c8a1ba39.jpg","width":"600"},{"desc":"","height":"400","title":"","url":"https://p0.ssl.img.360kuai.com/t01d5cb2861cd8c11cc.jpg","width":"600"},{"desc":"","height":"400","title":"","url":"https://p0.ssl.img.360kuai.com/t0166bf50c3daf81cd1.jpg","width":"600"},{"desc":"","height":"400","title":"","url":"https://p0.ssl.img.360kuai.com/t018213f4b097c86a9a.jpg","width":"600"},{"desc":"","height":"400","title":"","url":"https://p0.ssl.img.360kuai.com/t01f71317b458781514.jpg","width":"600"},{"desc":"","height":"400","title":"","url":"https://p0.ssl.img.360kuai.com/t014c88d7a5a78f00c0.jpg","width":"600"},{"desc":"","height":"400","title":"","url":"https://p0.ssl.img.360kuai.com/t011665db5d2df2221b.jpg","width":"600"},{"desc":"","height":"400","title":"","url":"https://p0.ssl.img.360kuai.com/t01819e3caa01a2507a.jpg","width":"600"},{"desc":"","height":"400","title":"","url":"https://p0.ssl.img.360kuai.com/t0130ebe260d212087f.jpg","width":"600"},{"desc":"","height":"400","title":"","url":"https://p0.ssl.img.360kuai.com/t0127d7eb92aa6c06ae.jpg","width":"600"},{"desc":"","height":"400","title":"","url":"https://p0.ssl.img.360kuai.com/t01b9e4c050f01a5f0e.jpg","width":"600"},{"desc":"","height":"400","title":"","url":"https://p0.ssl.img.360kuai.com/t0199758da0a3779f51.jpg","width":"600"},{"desc":"","height":"400","title":"","url":"https://p0.ssl.img.360kuai.com/t015889055598c3a225.jpg","width":"600"},{"desc":"","height":"400","title":"","url":"https://p0.ssl.img.360kuai.com/t01231444e8e8045dee.jpg","width":"600"}]}],"original":0,"pat":"art_src_1,fts0,sts0","powerby":"hbase","pub_time":1678352215000,"pure":"","rawurl":"http://zm.news.so.com/85914a9644be207b66dd3fdef8e07233","redirect":0,"rptid":"1e512b1d67119d72","rss_ext":[],"s":"t","src":"什么值得买","tag":[{"clk":"kcar_1:摩托车","k":"摩托车","u":""}],"title":"价格35的拼装摩托车值得买吗,质量怎么样,安装要扩孔削卡榫吗

窦宙卓2069为了提高模具所加工的零件精度,应采取哪些措施 -

苏贞谭18039576119 ______ 提高模具的制作精度,在加工中,加强检验巡检,加工零件尺寸出现问题,应及时对模具进行修复,以免出现批量性的质量事故.

窦宙卓2069镗孔和扩孔的区别

苏贞谭18039576119 ______ 镗孔是在已经有了一个孔的基础上,(如工件本来就有一个孔,或先用钻头打了一个... 所以我在此用“成形刀”一词). 镗孔与扩孔的主要区别在于镗孔时,每一次把孔加...

窦宙卓2069钳工钻床钻10mm的孔 我分二次钻 第一次先用3mm的钻头打底孔,在用10mm的钻头钻出孔?还有这种方法对吗这种方法是叫扩孔吗?扩孔工具有那些? -

苏贞谭18039576119 ______[答案] 是叫扩孔,但是你用的方法有问题.第一次钻底孔的钻头太小.至少要最终钻孔直径的50%-70%的钻头.也就是说,用5-7个的钻头最合适.

窦宙卓2069有谁可以科普一下模具有那些孔要精度和不要精度的吗 -

苏贞谭18039576119 ______ 你也没说什么模具啊,但凡模具,导向柱和上下模精度要求都高,螺丝孔要求不那么高也不能偏差大了啊,所以,做模要仔细些,最好全部孔位做精准

窦宙卓2069车床上怎样钻孔 -

苏贞谭18039576119 ______ 多数普通车床钻孔都是手动的,个别的型号可以通过大托板带动尾座的方式自动钻孔.重型机床的尾座是可以自动进给的.钻孔需要的力 是和钻头直径成正比的,一般情况下,只要钻头角度刃磨没有太大的问题,通过修磨横刃钻35毫米的孔都不是太费力,而且钻大直径的孔时通常都会先钻一个较小的孔,然后再扩孔的方法完成.

窦宙卓2069拉孔的精度有多大 -

苏贞谭18039576119 ______ 拉削是一种高精度加工方式,表面粗糙度一般在1.25-5之间

窦宙卓2069机械加工中如何提高细长孔工件的加工精度? -

苏贞谭18039576119 ______ 细长孔加工方法:打中心孔—钻孔—扩孔—铰孔. 铰孔及注意事项 1浮动铰刀的设计 扩孔有纠正位置精度的能力,实践证明.而铰刀铰孔只能保证尺寸、形状精度和减少孔的外表粗糙度,但不能有时,纠正孔的位置精度.由于机床的振动,...

窦宙卓2069用钻套钻孔哪种加工获得的孔精度最高?通常情况下,扩孔、钻孔、铰孔

苏贞谭18039576119 ______ 一般的,钻孔精度IT9,粗糙度12.5.扩孔精度IT8,粗糙度6.3.铰孔精度IT7,粗糙度3.2~1.6.