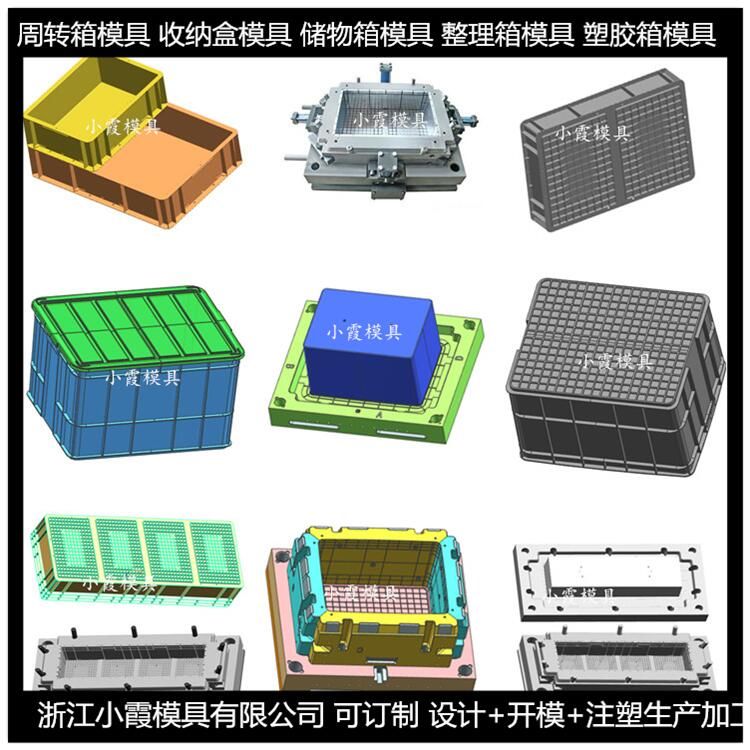

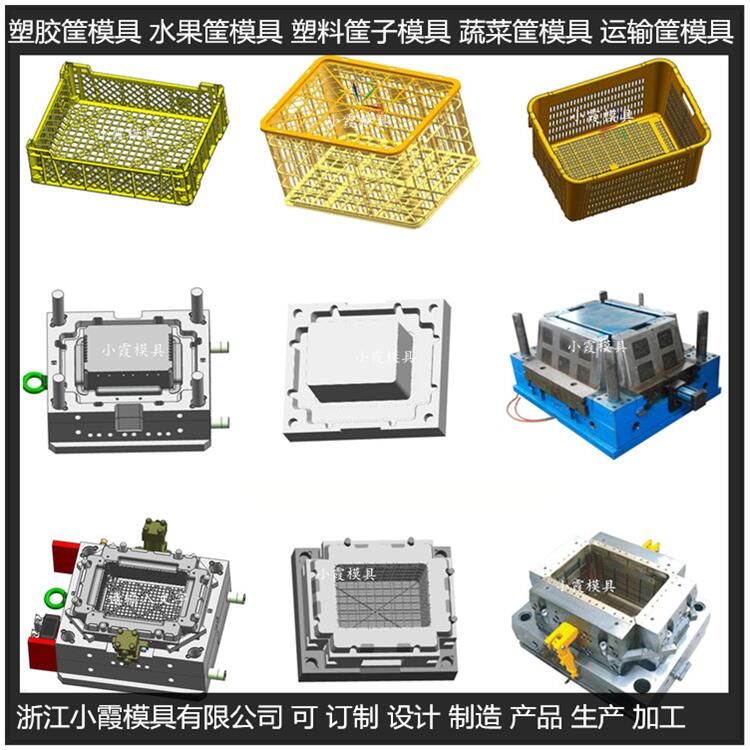

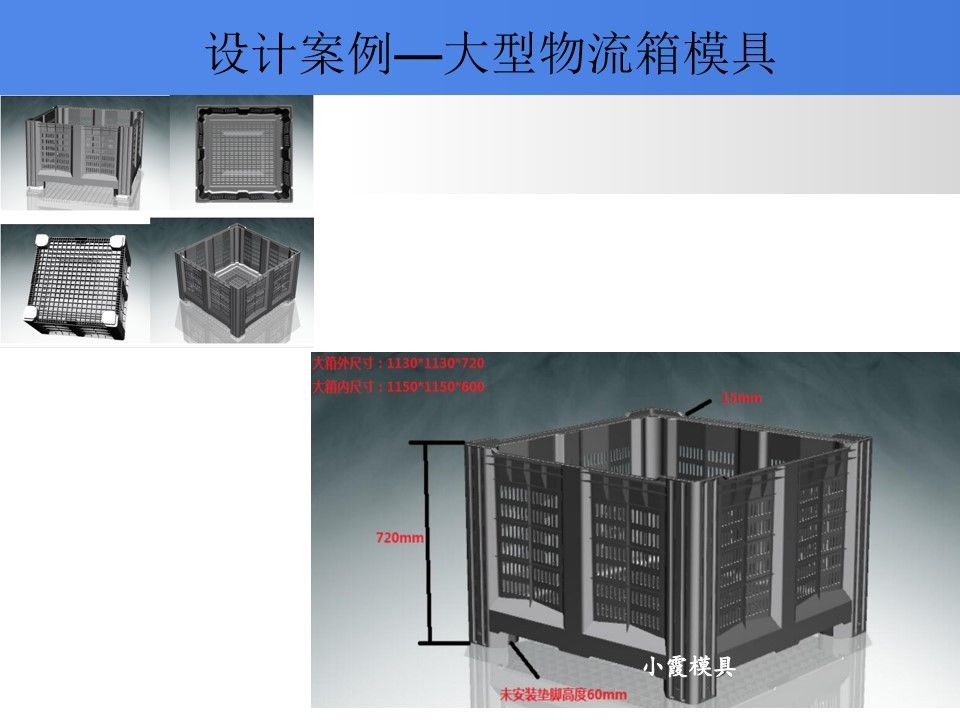

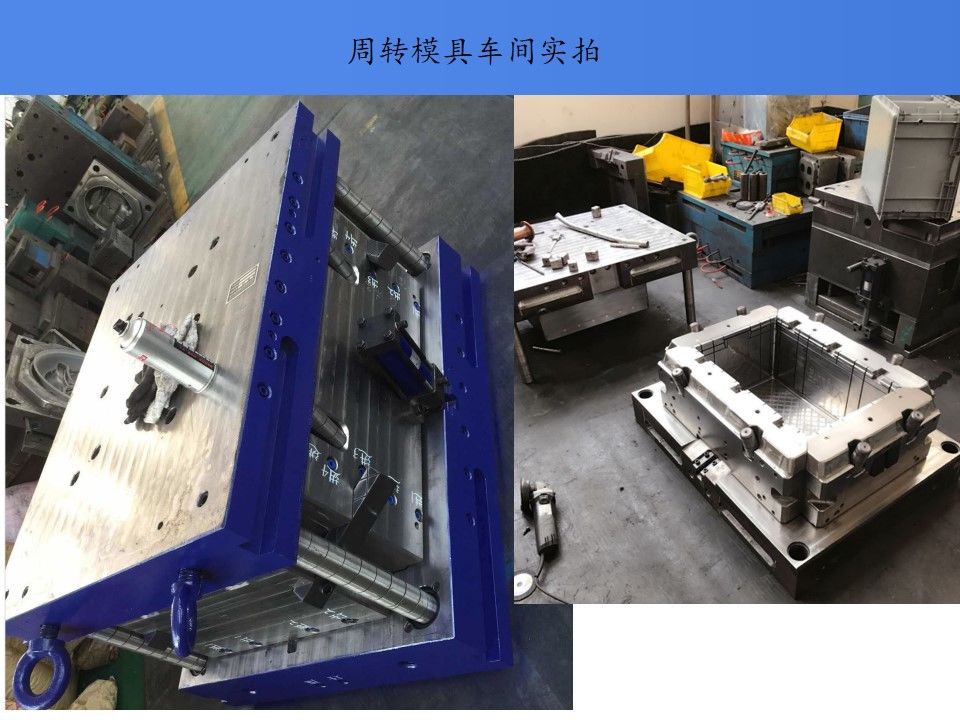

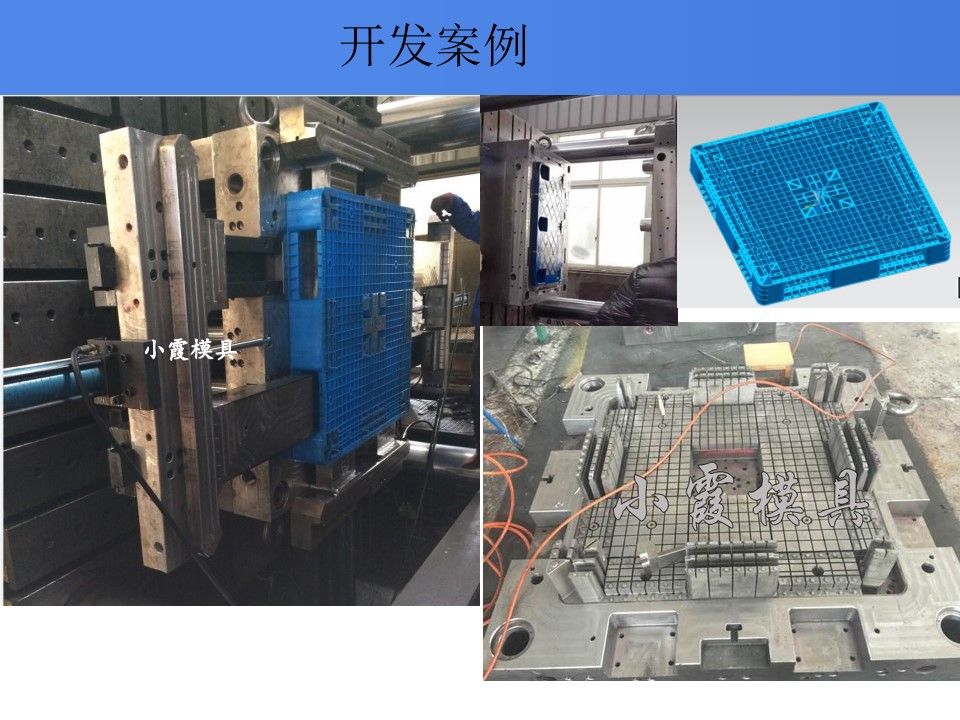

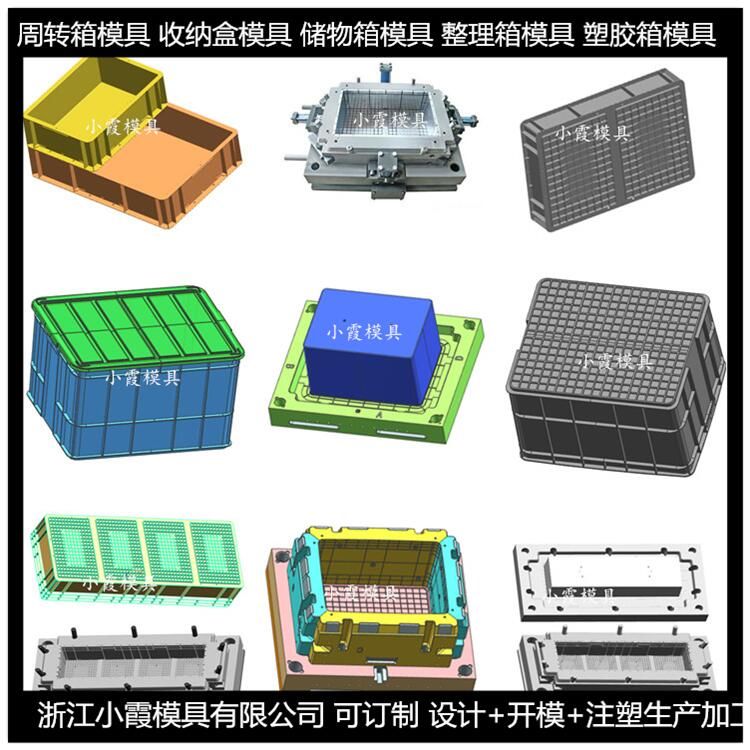

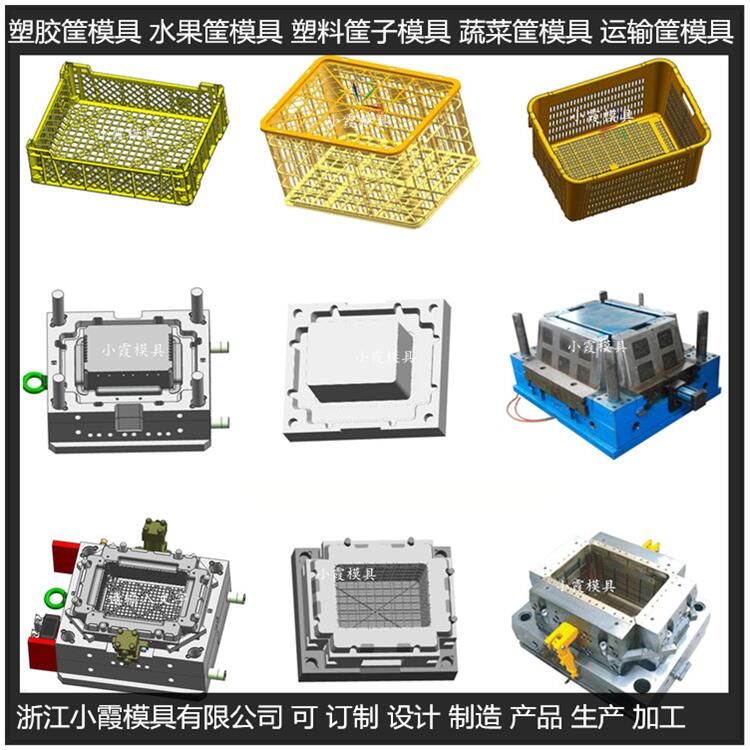

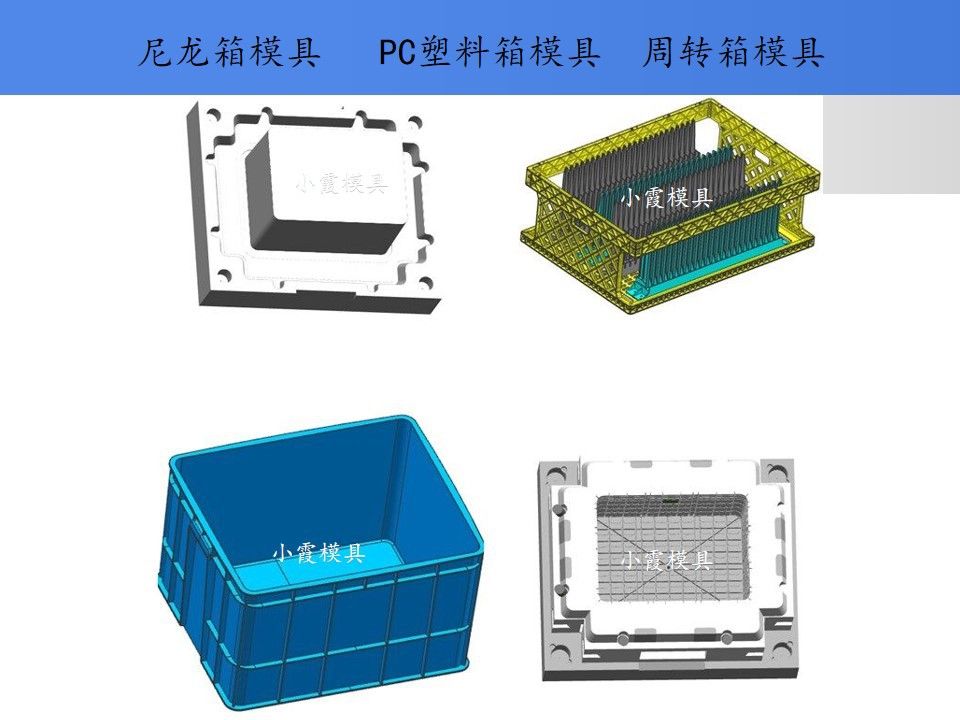

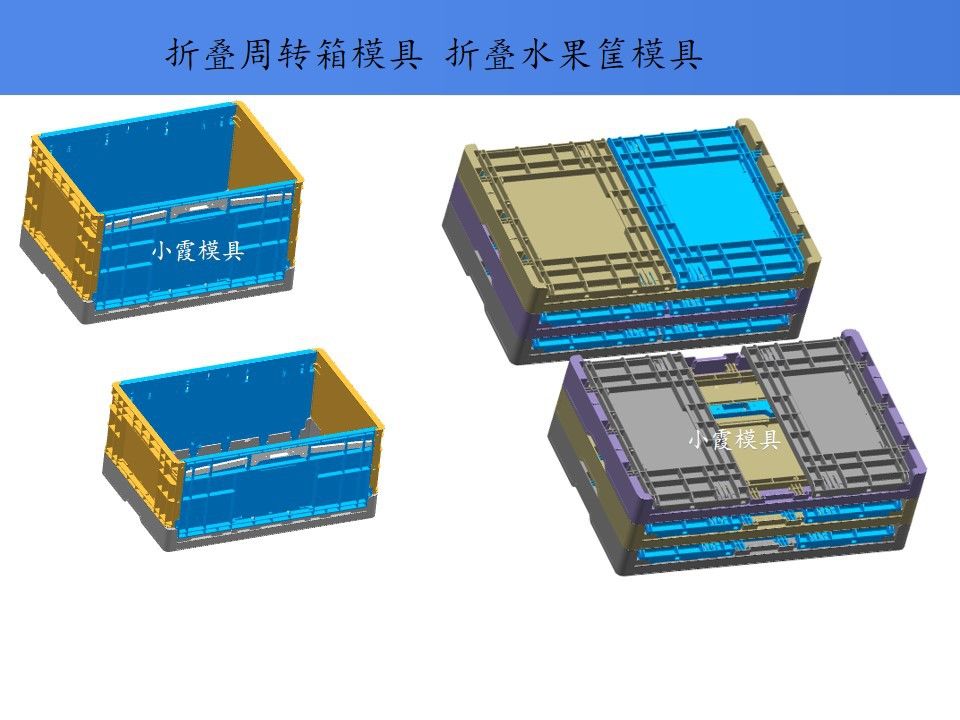

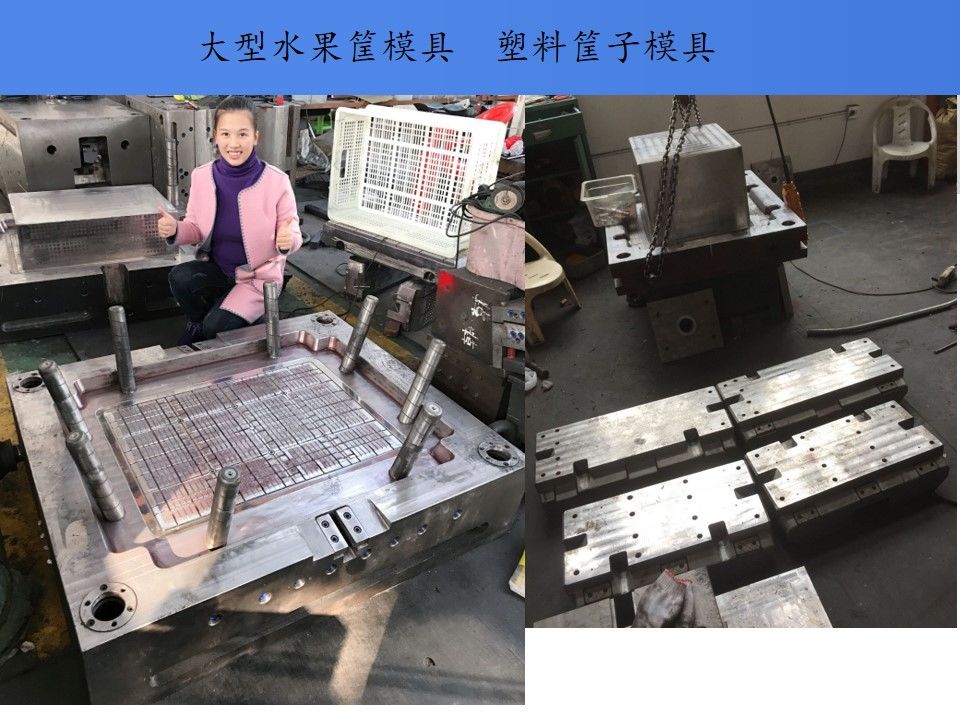

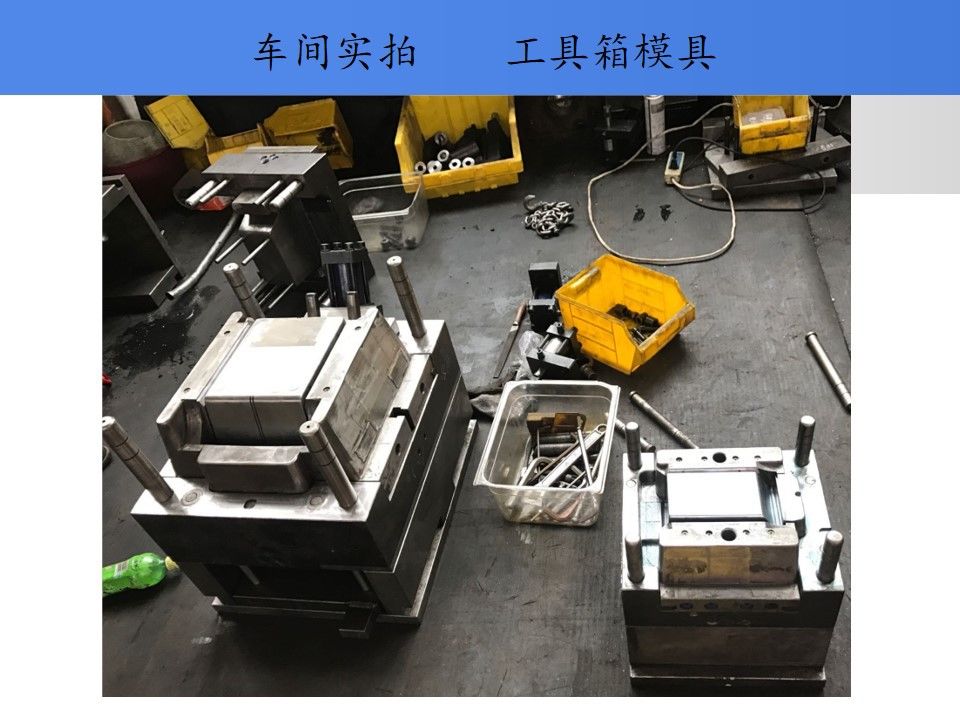

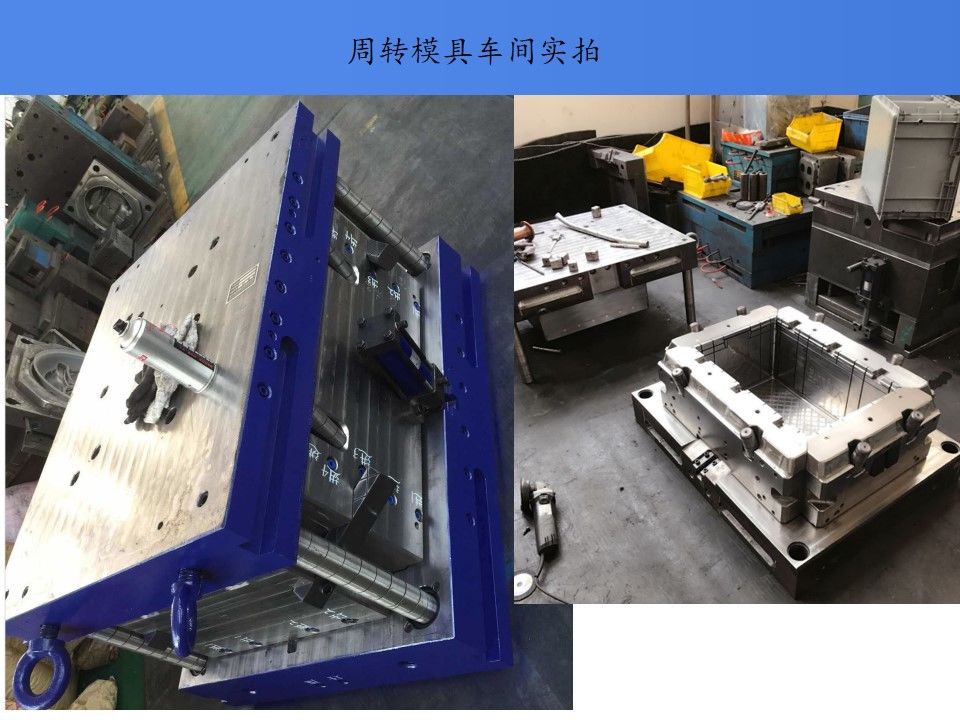

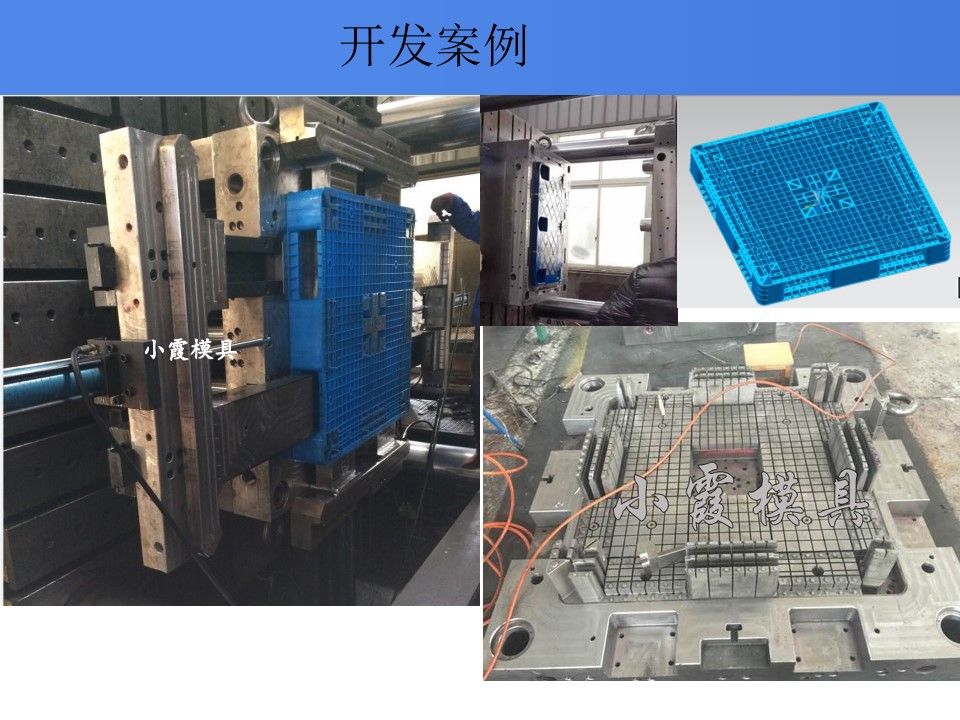

周转箱模具/注塑成型模具支持定制

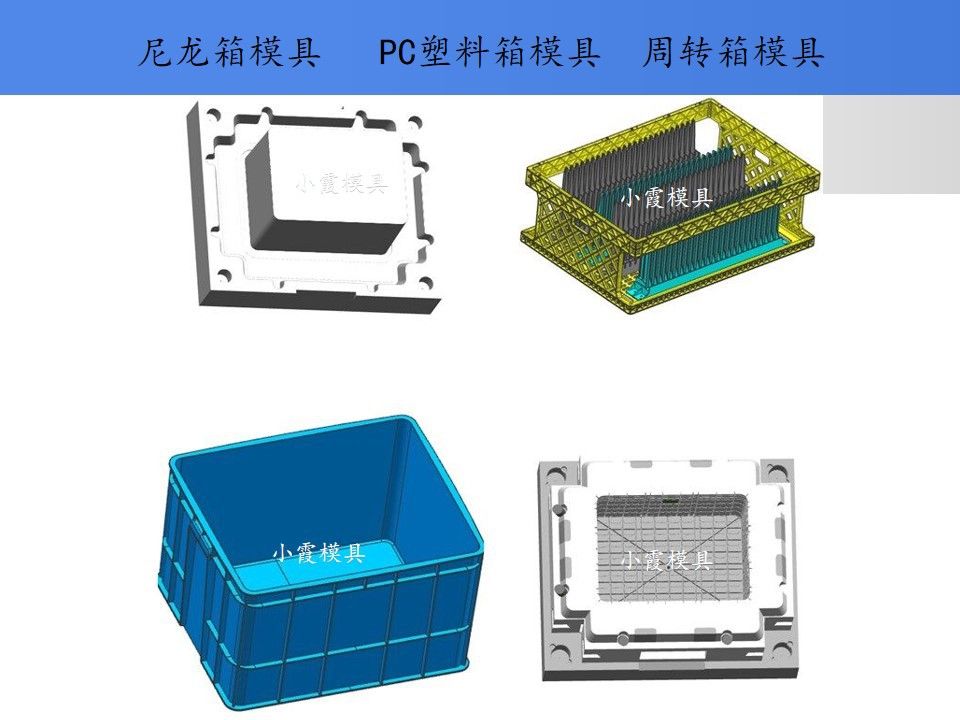

周转箱注塑模具

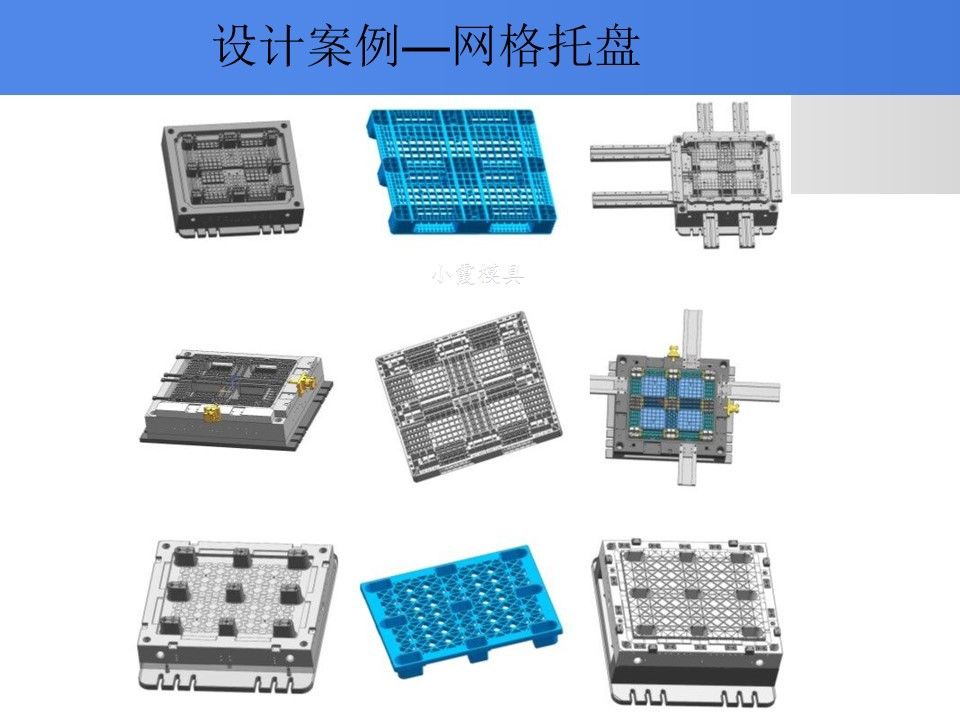

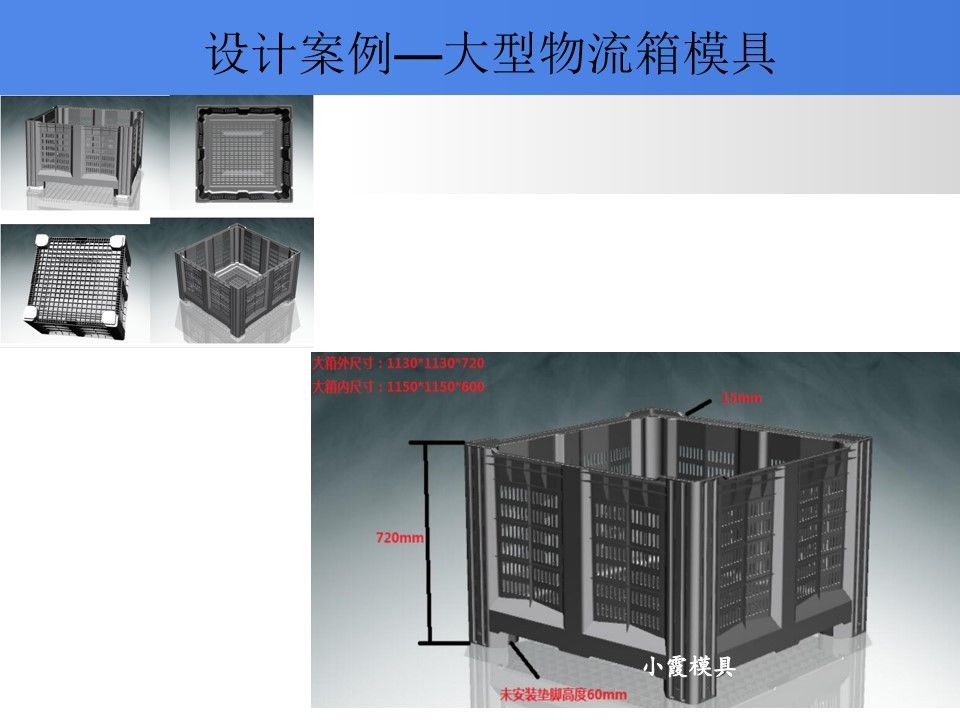

小霞模具有强大设计团队可接受:提供样品,或者,三维图纸,二维图纸,可以报价开模,欢迎您来咨询报价!

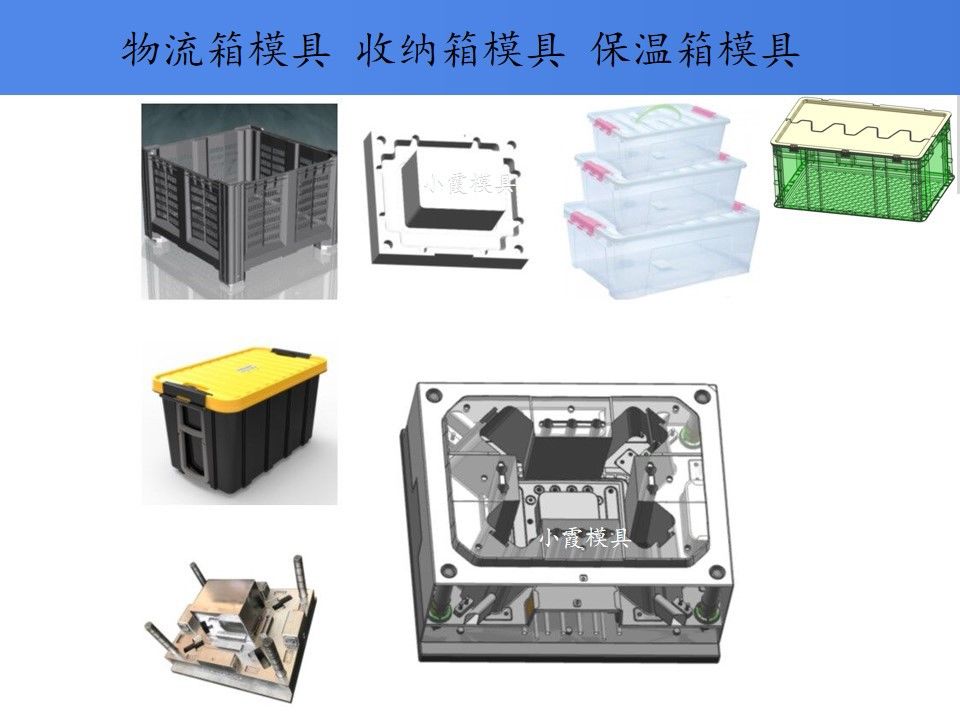

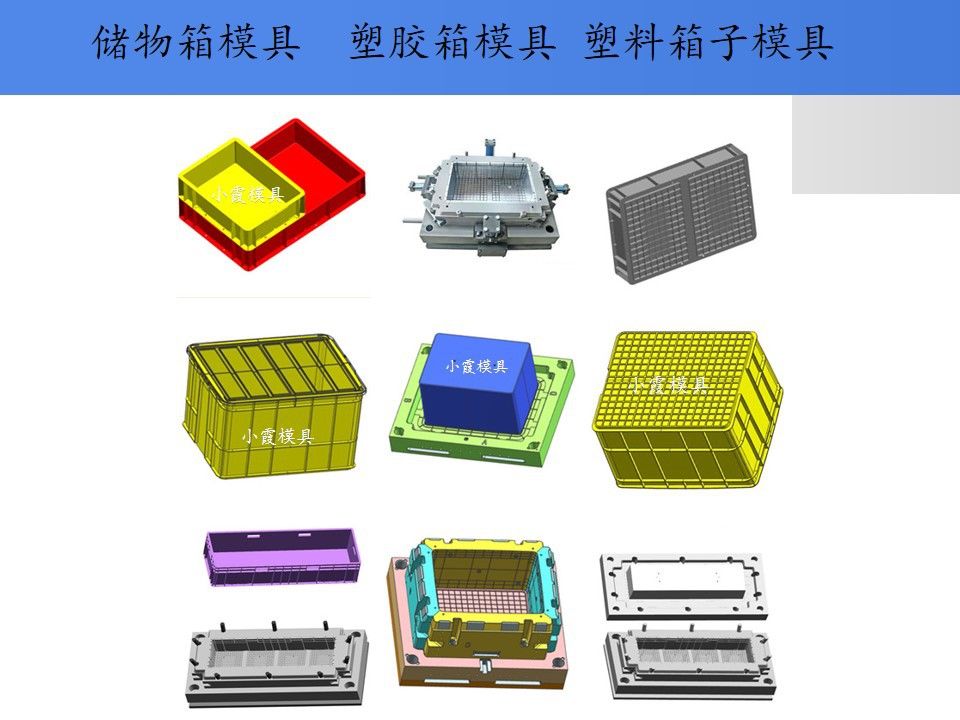

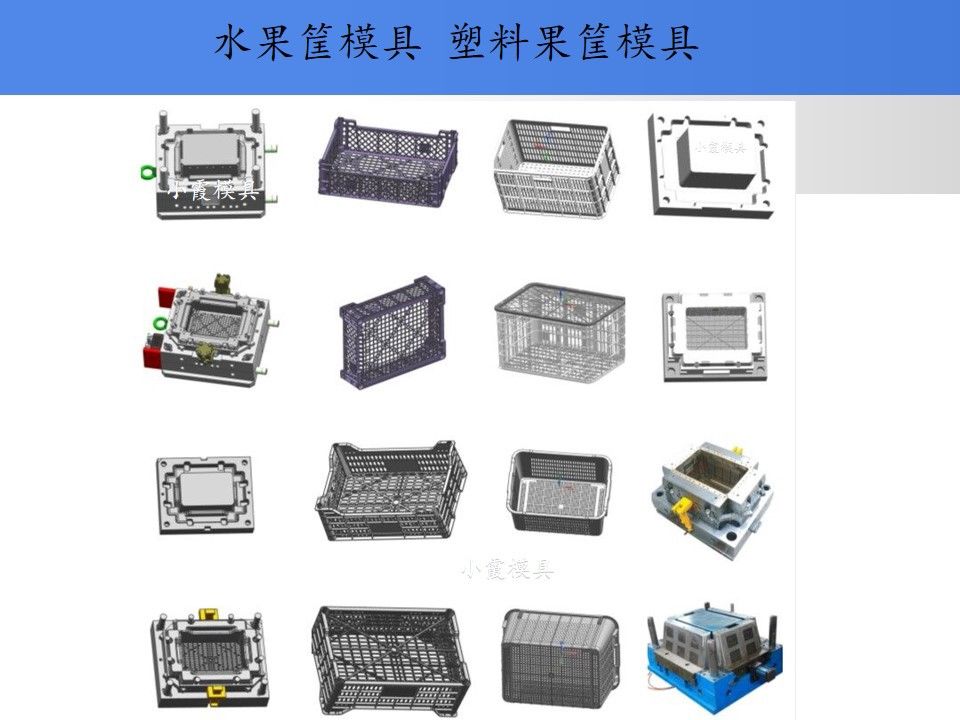

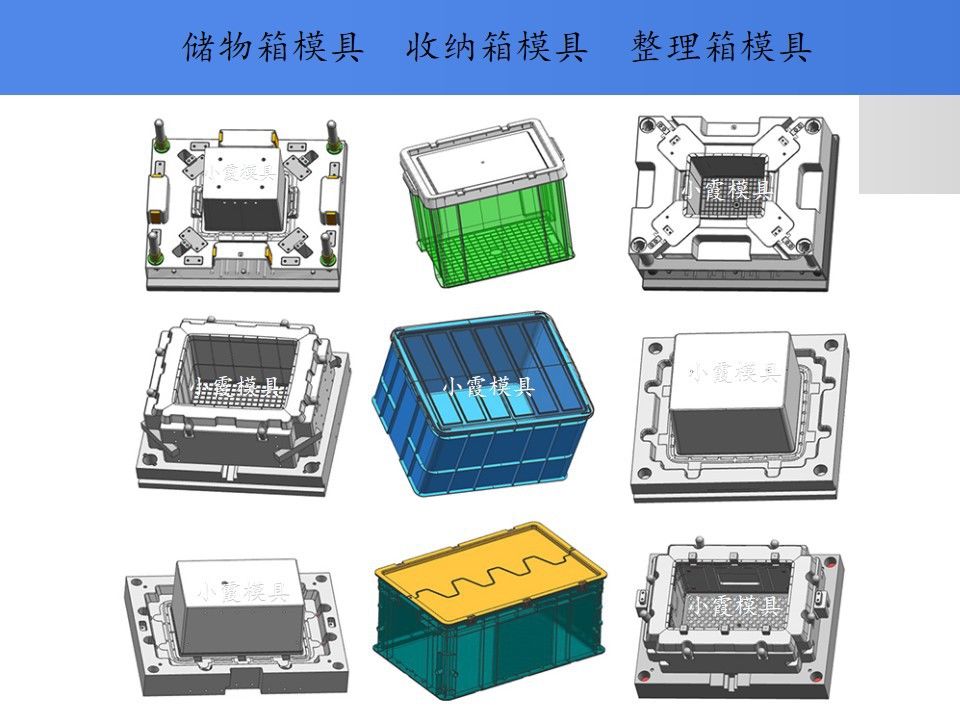

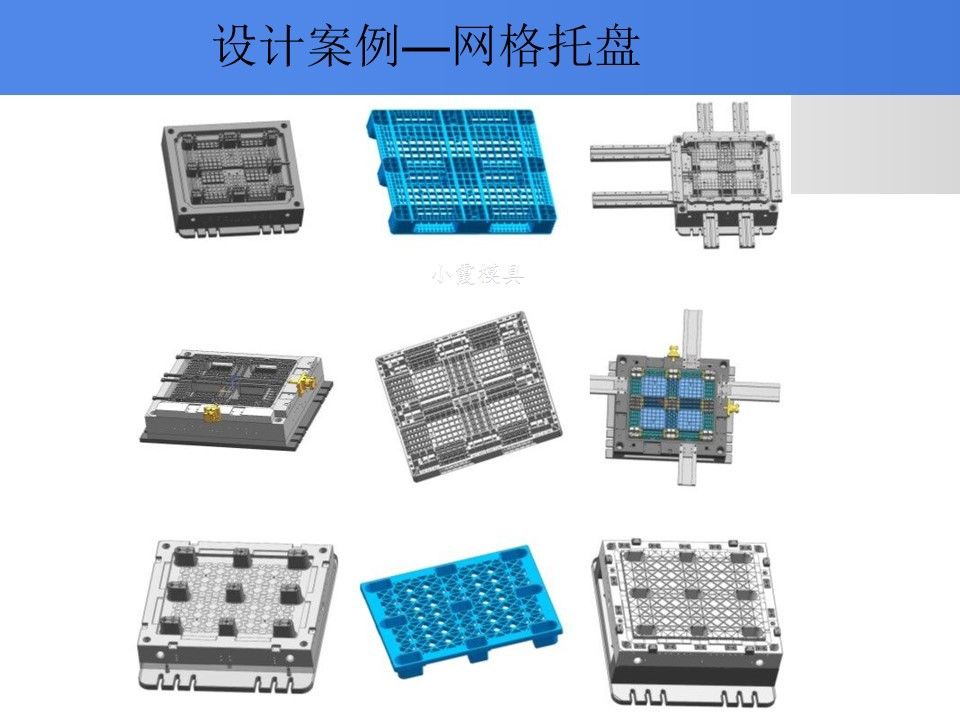

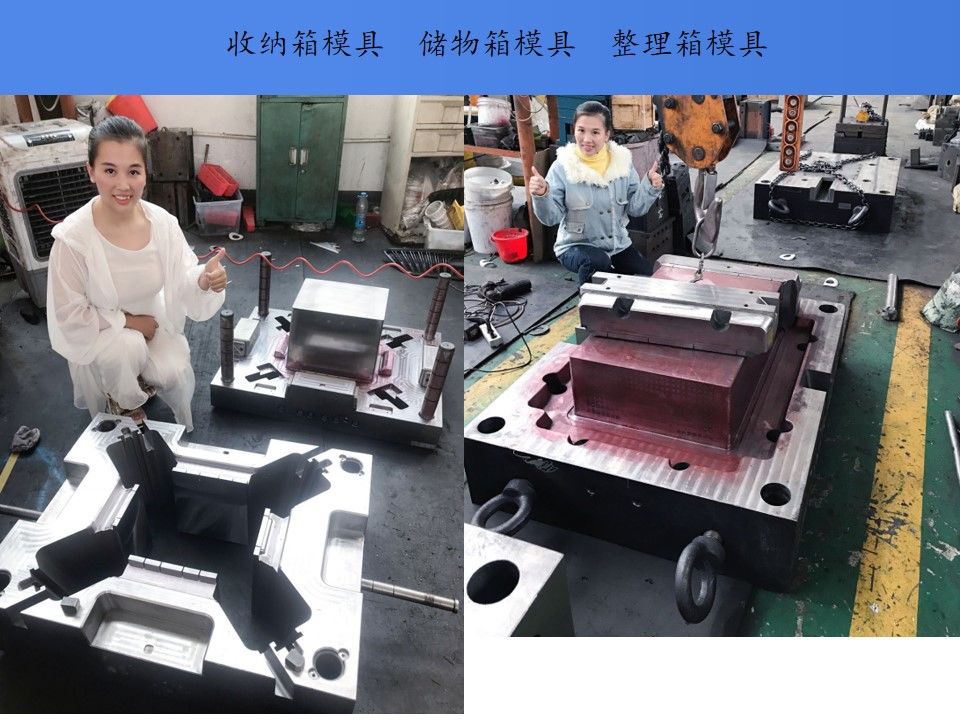

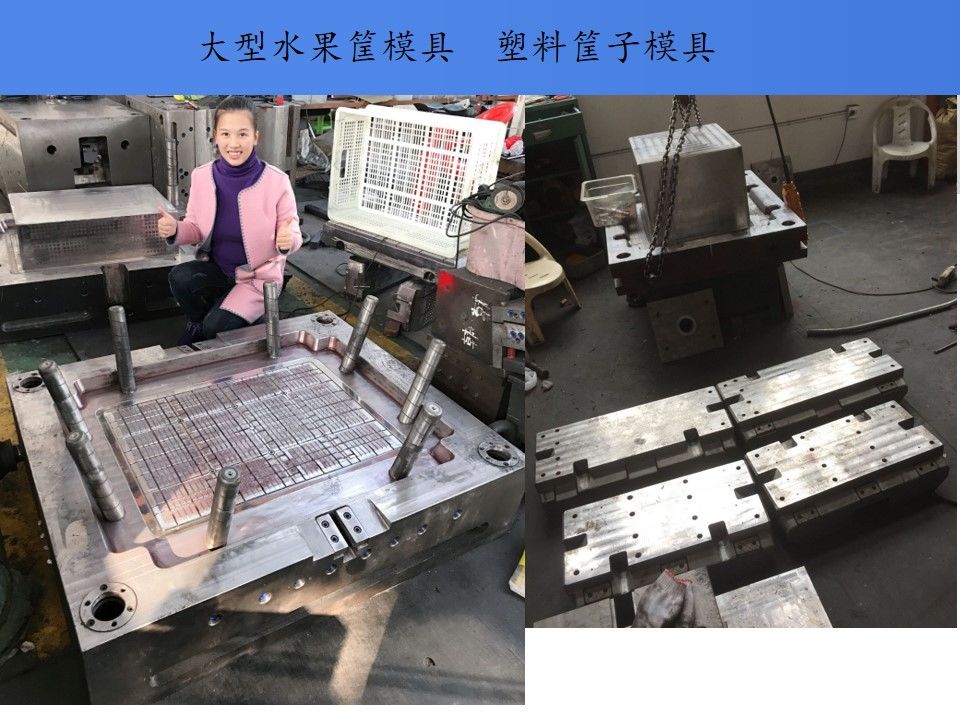

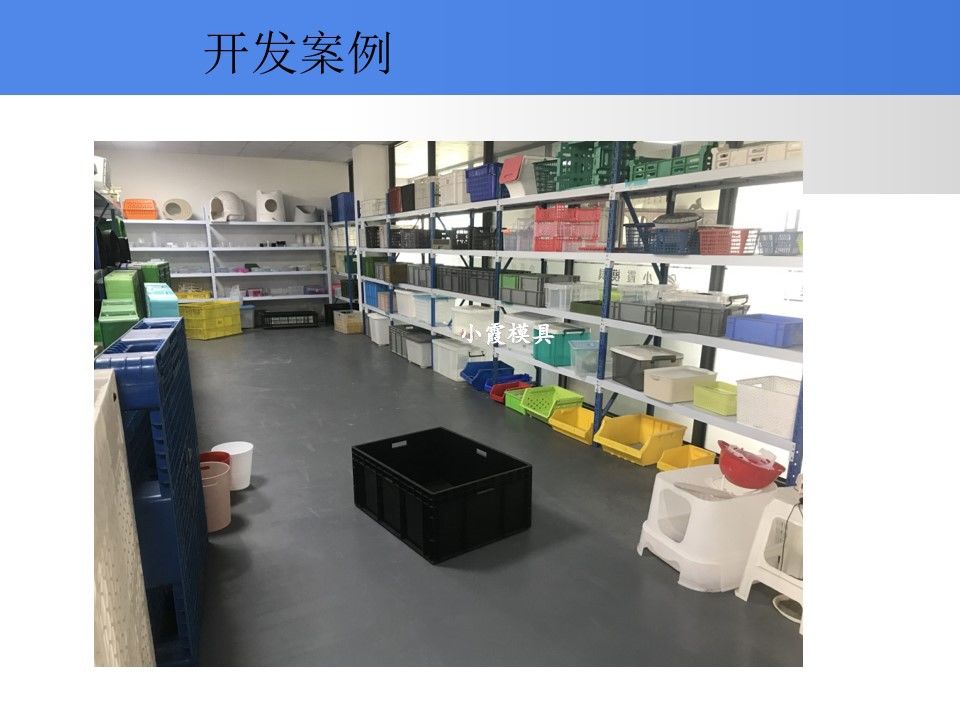

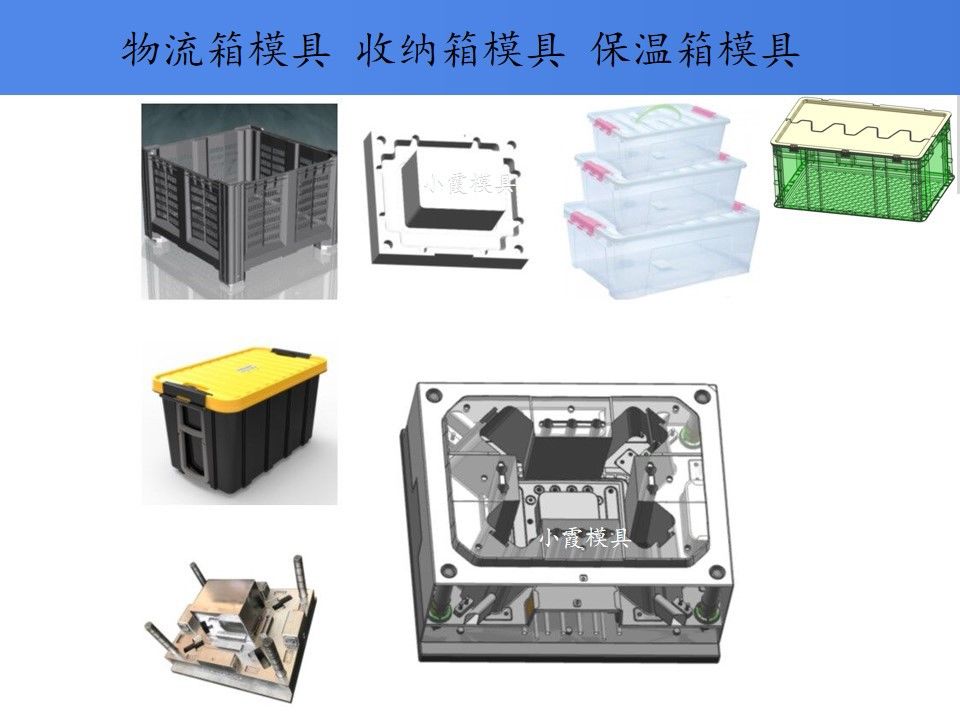

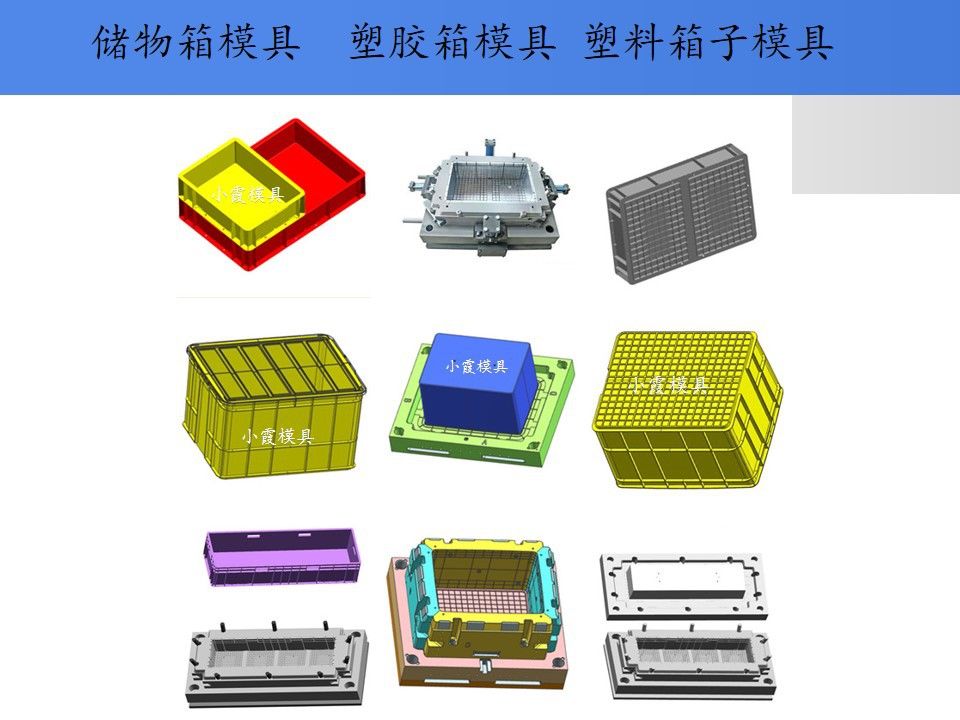

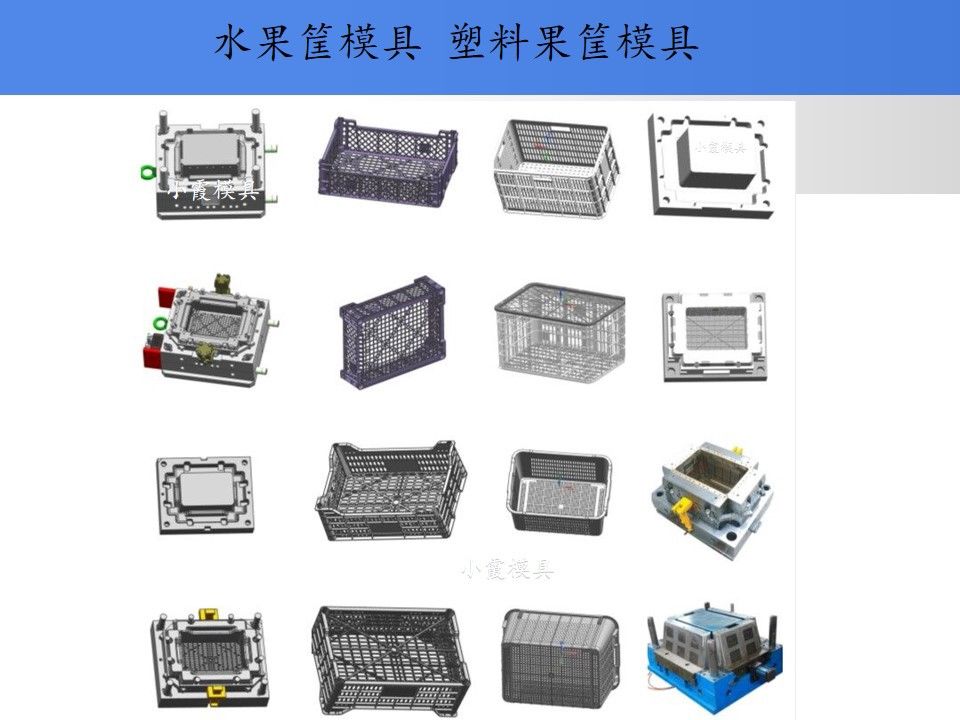

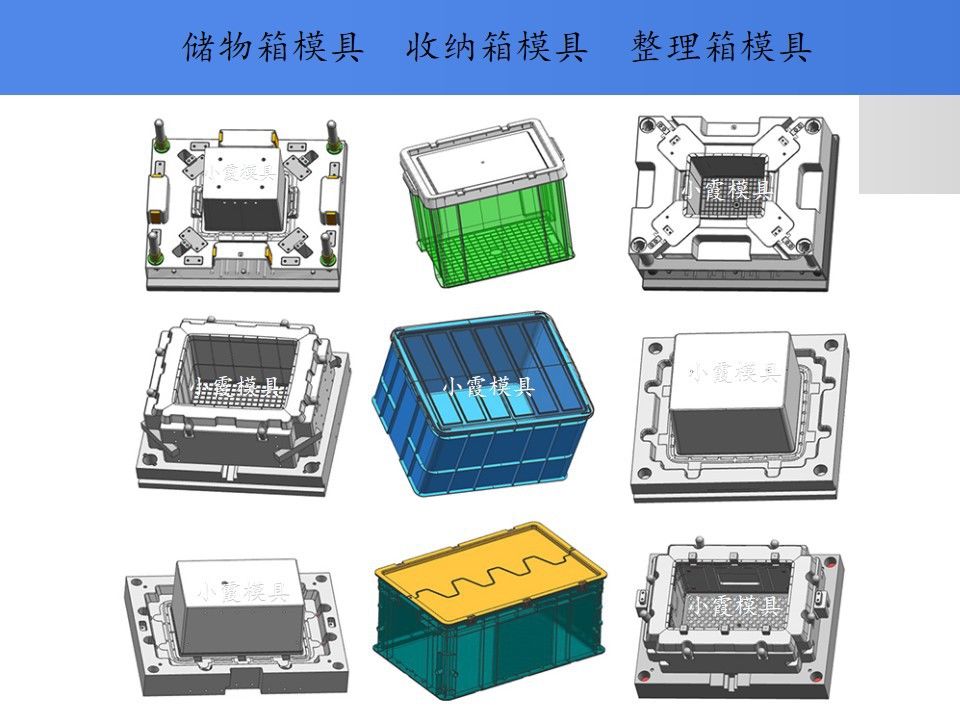

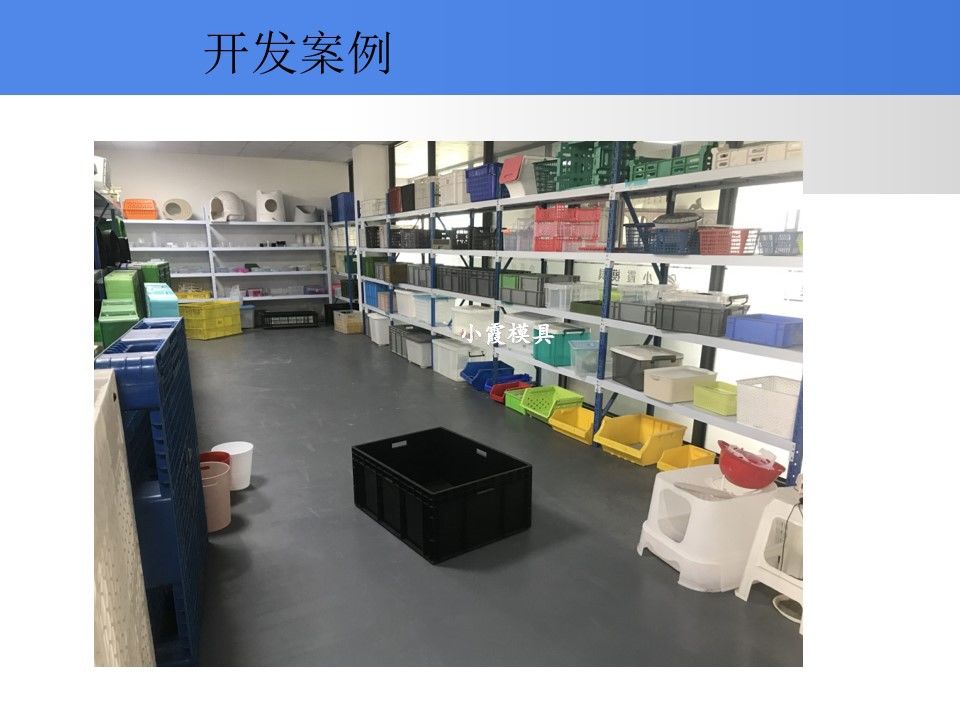

收纳盒塑料模具储物盒塑料模具收纳柜塑料模具塑胶箱塑料模具

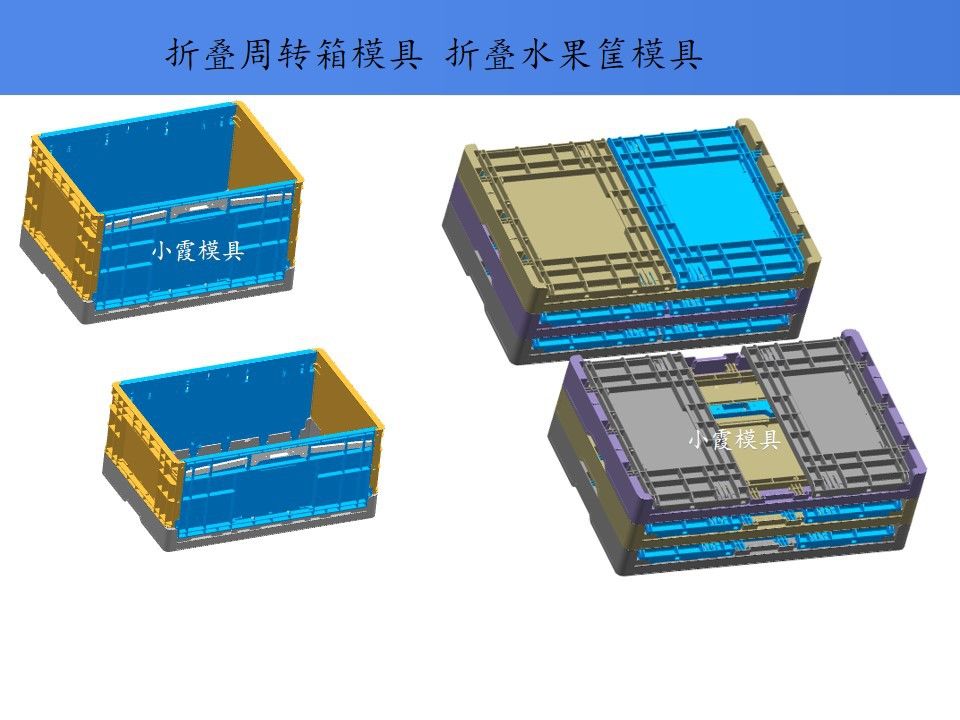

箱子塑胶模具储物箱塑胶模具折叠箱塑胶模具 周转箱塑胶模具

收纳盒塑胶模具储物盒塑胶模具收纳柜塑胶模具塑胶箱塑胶模具

型号: | 按要求定制 |

腔数: | 1出1 |

模架: | LKM, ISM标准,HASCO 或按照客户要求 |

模具材质: | P20, 718H, H13, 2344, 2316, NAK80 |

模具流道系统: | 冷流道/热流道 |

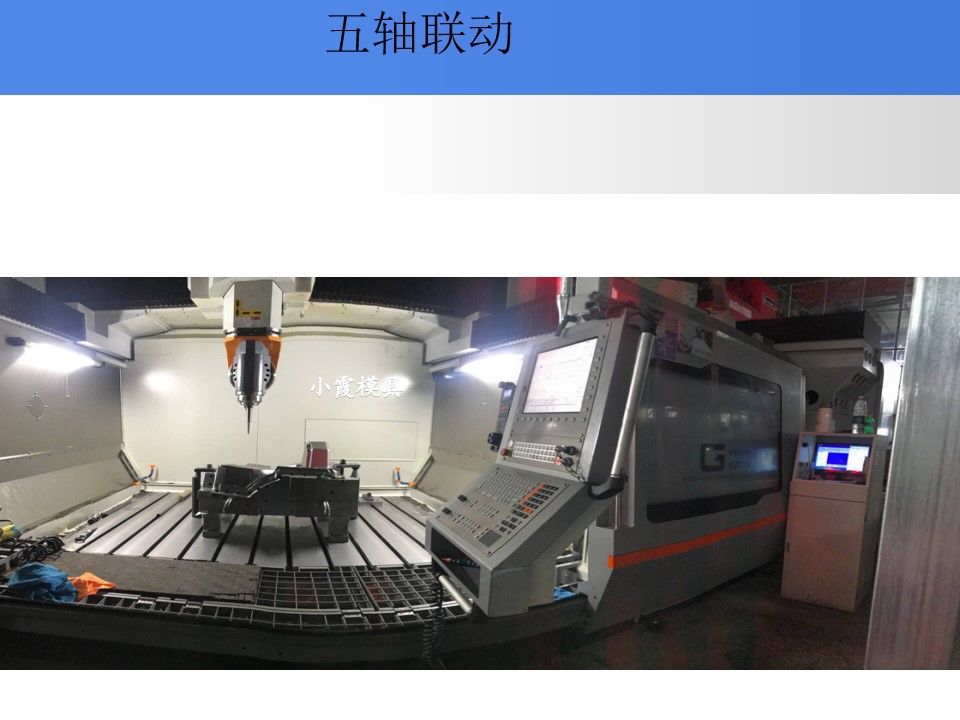

设计软件: | UG; PROE; |

塑料材质: | PP, ABS, HDPE, PC, PVC, PA6, PA66, PET etc. |

模具寿命: | 500,000次-3,000,000次 |

模具尺寸: | 根据产品设计 |

模具重量: | 根据产品设计 |

样品: | 根据产品设计 |

普通模具交货期: | 35-50天 |

高要求精密模具 | 55-85天 |

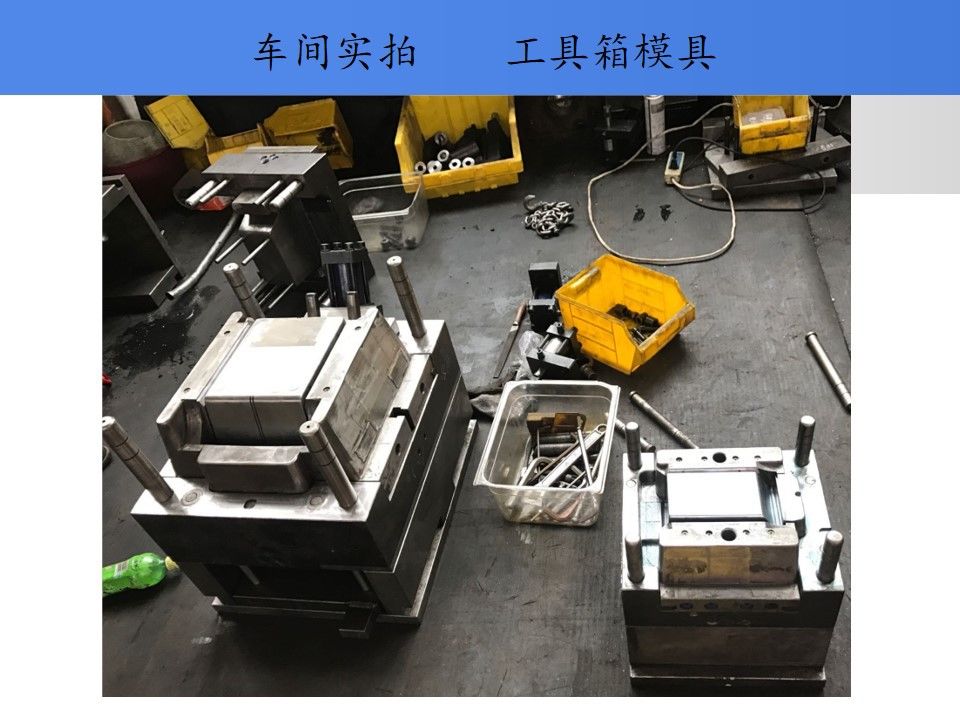

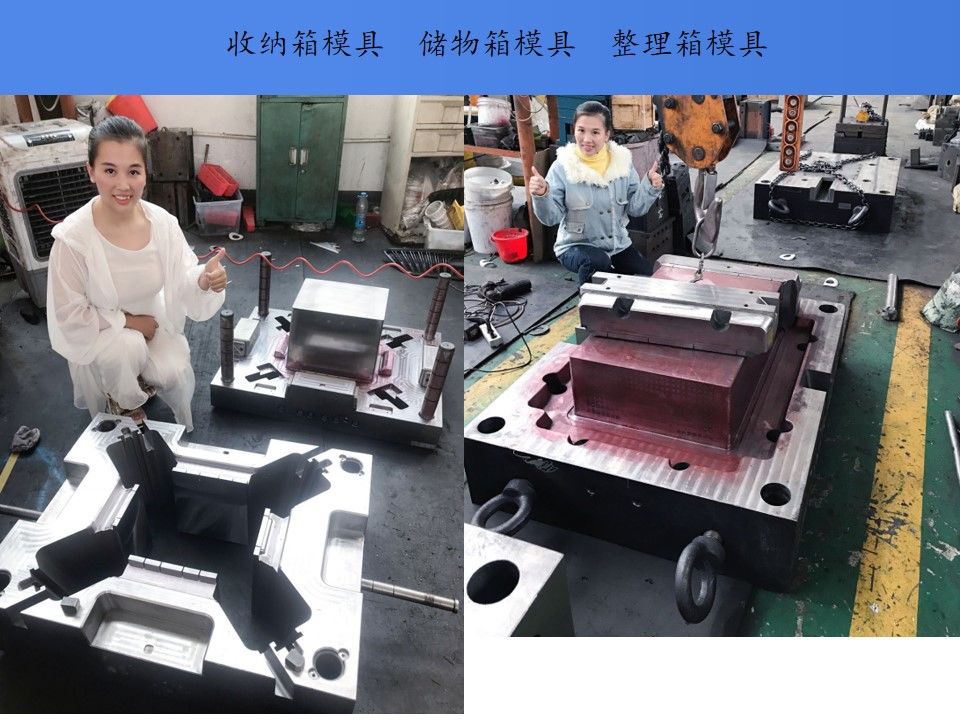

周转箱模具 塑胶箱模具 收纳箱模具 储物箱模具

浙江小霞模具公司,主要:模具制造,注塑加工.产品 处理:喷漆,烤漆,水转印,电镀,丝印,热转印,在我们公司定做注塑模具可享受大优惠, 我为自己 你舍得花钱,我舍得做,一分钱一分货,舍得换新款时尚型。你不舍得花钱,我给你做 大气经典型模具,欢迎您来厂订购模具 !

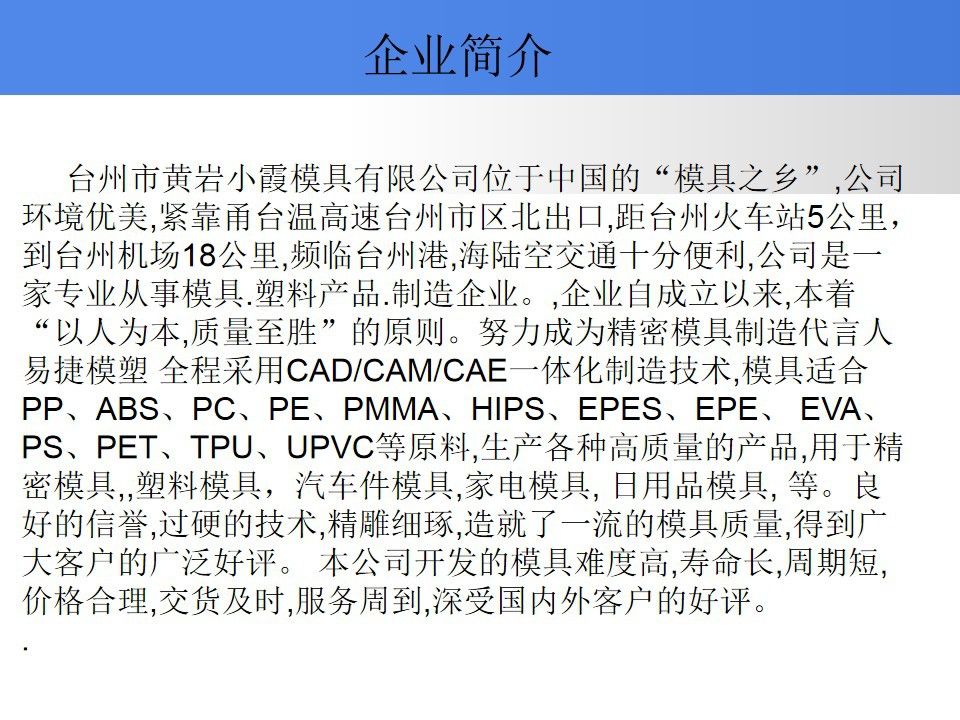

一、公司简介:

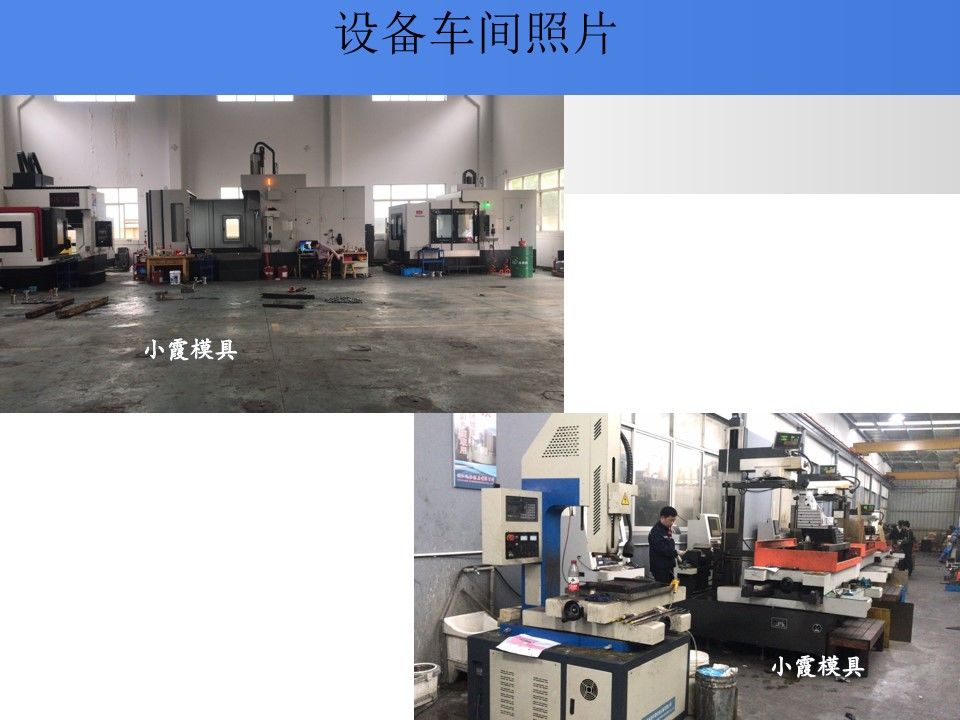

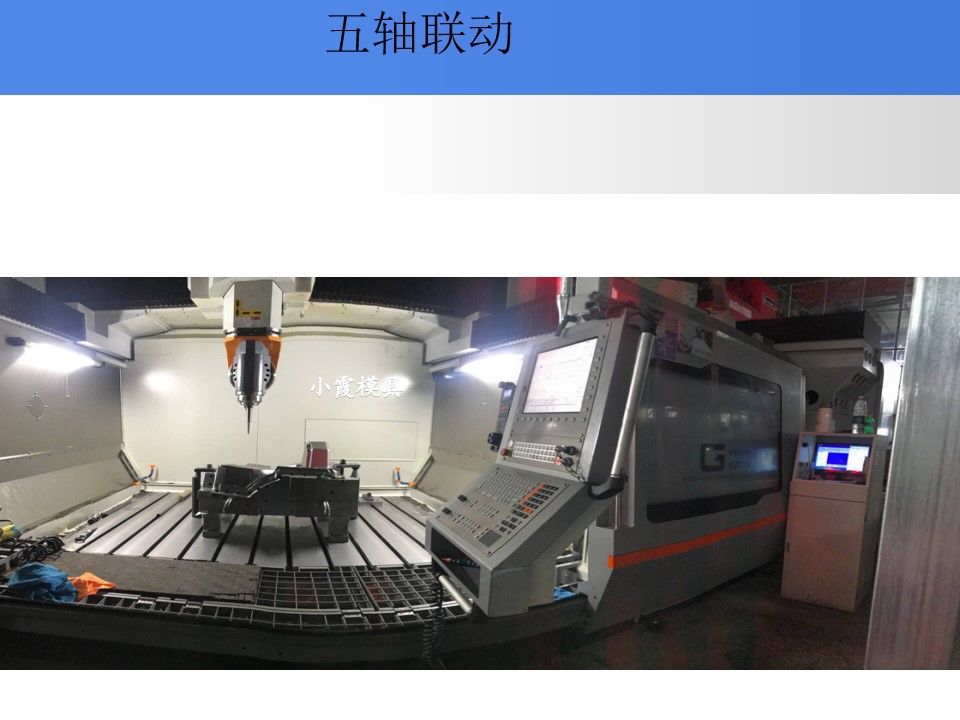

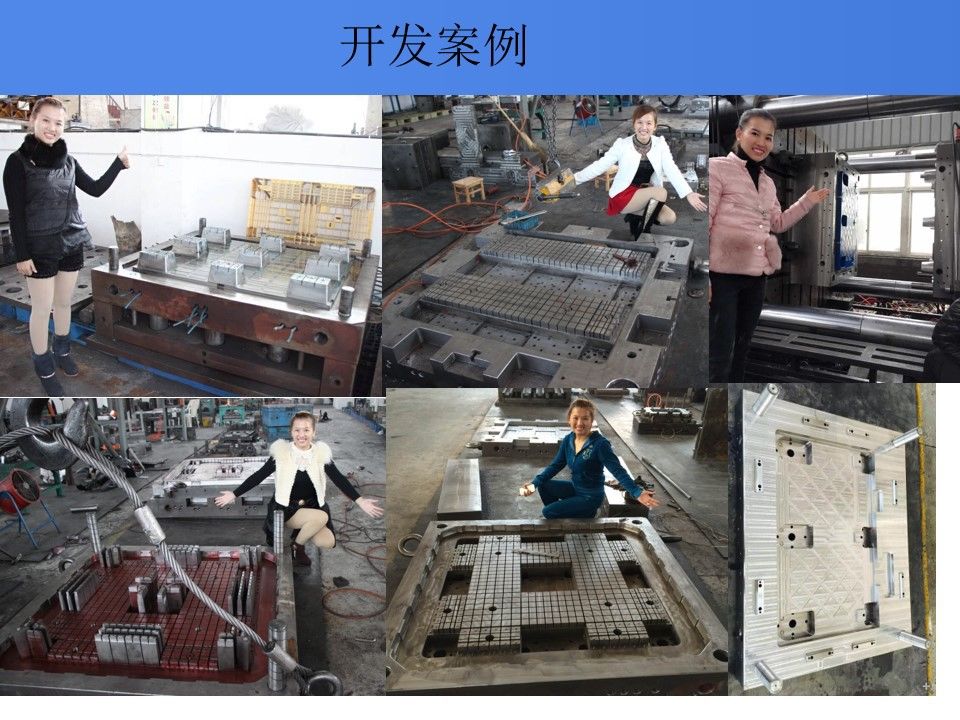

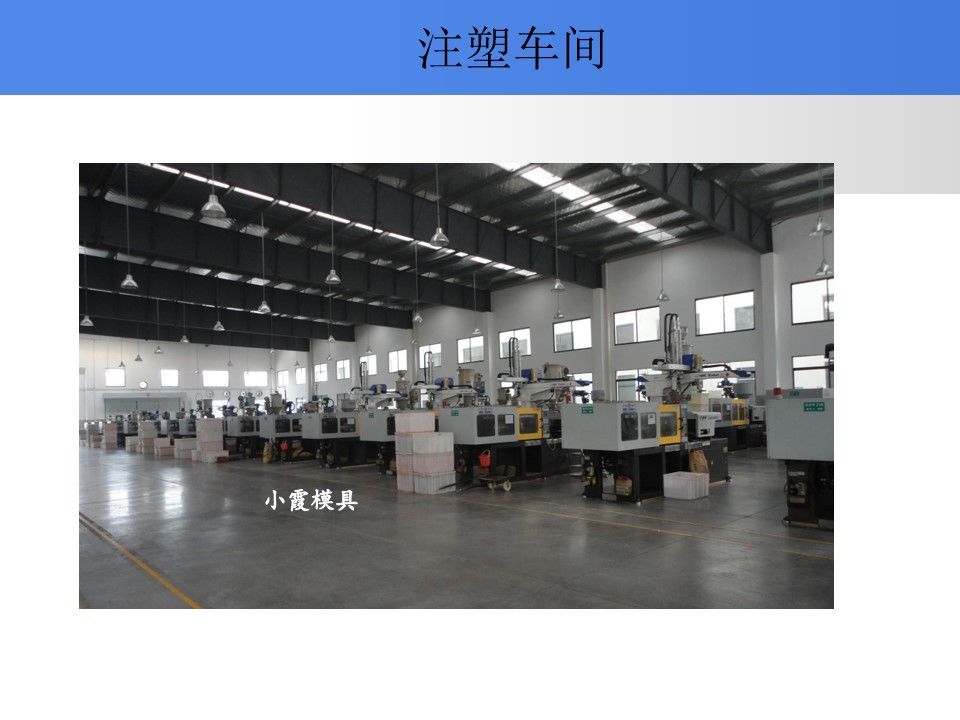

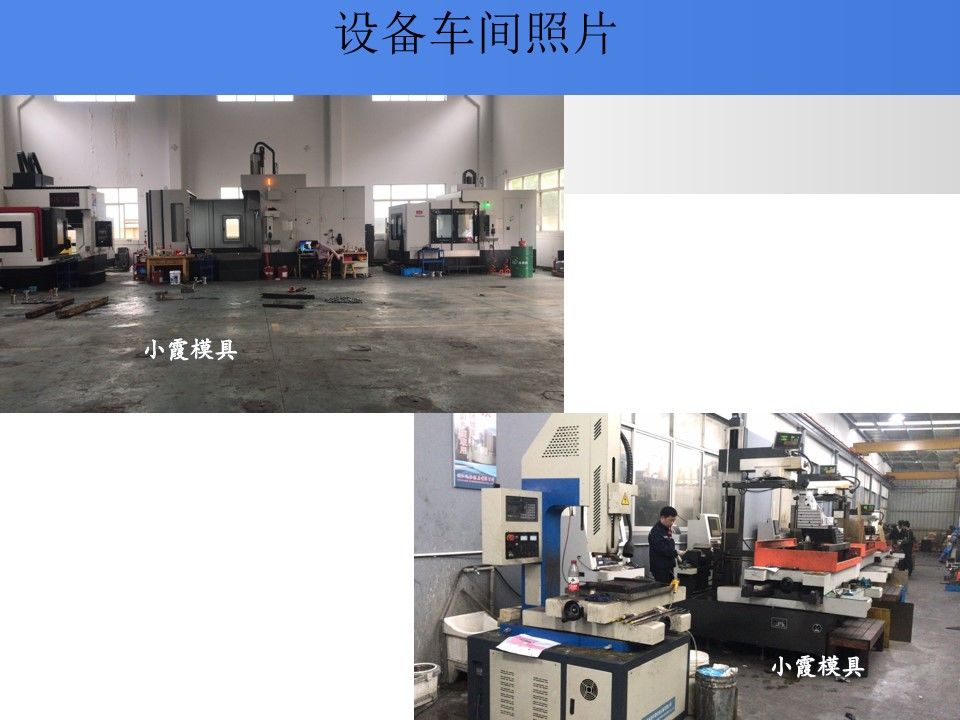

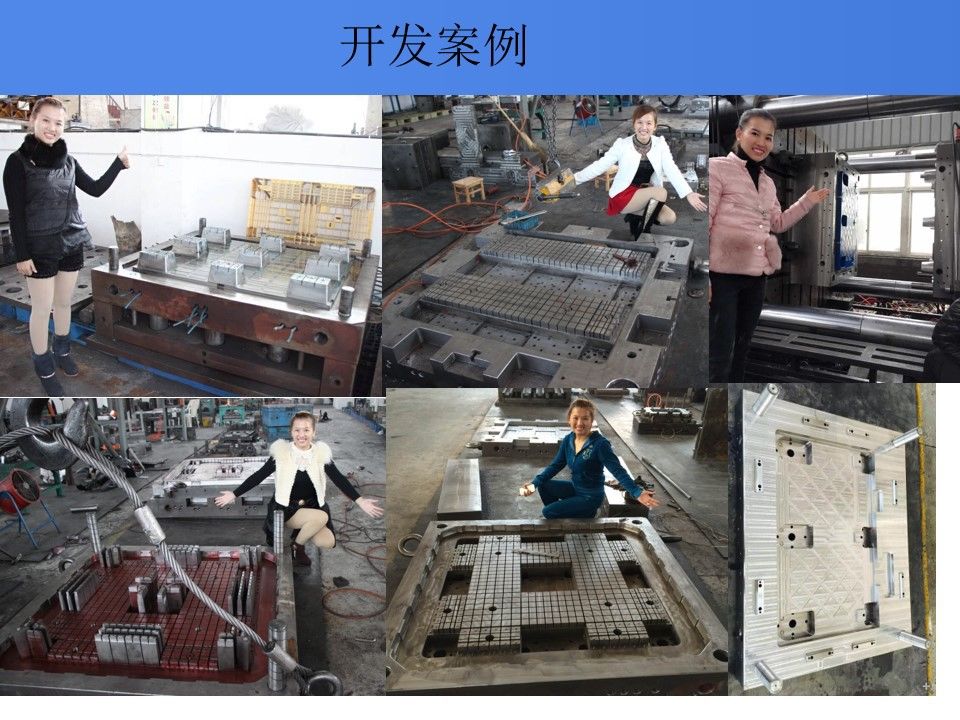

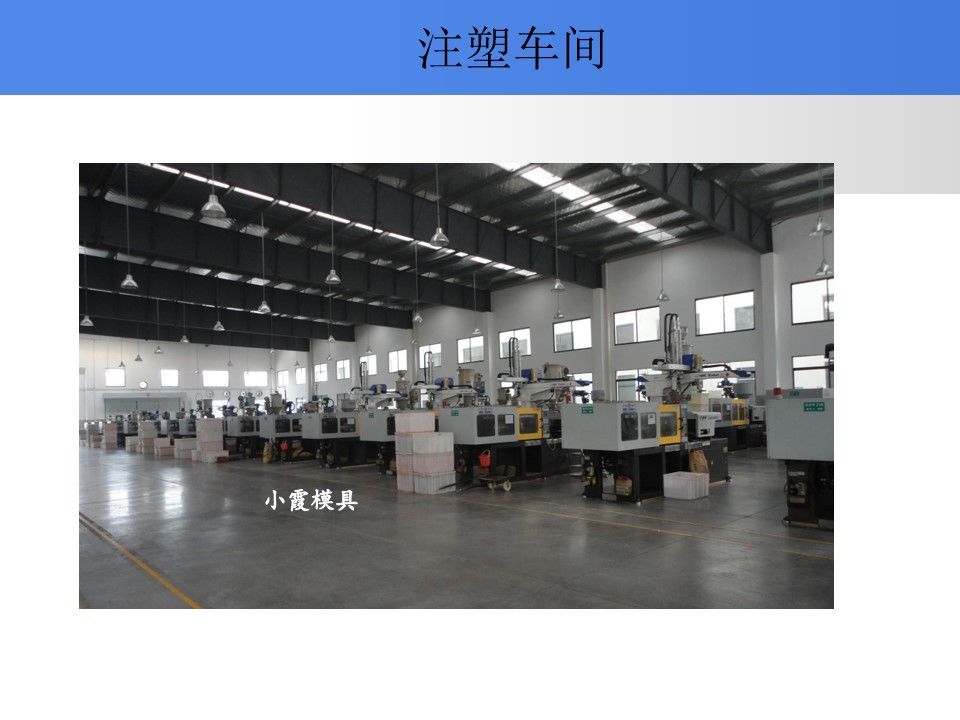

小霞模具工贸有限公司目前公司员工人数突破百人,拥有自己的模房,加工中心,试模中心,拥有自主研发产品的能力。公司目前技工5人,中级技工10人,设计团队人数为15人,他们时刻贴心的在为客户服务。公司占地面积6000平米,加工车间,设备齐全。我们可以根据客户的来样或者来图加工模具,在黄岩模具加工厂家中服务做的比较到位的厂家。目前国内可获对我们的评价很高,这不仅仅是我们给客户提供了 的模具产品,更多体现的是我们 的服务!

公司迎来了崭新的历程,公司从国内市场走向国际市场,打开了迈向国际化道路,几年下来公司在东南亚、 服务了不少的客户,这些客户群体中有不少是长期的在跟我们合作。我们要追求的是品质,因为只有产品了,客户的收益才能稳定并成直线上升,也有这样,客户才能放心的跟我们合作,并建立长久合作关系!

我们的诚诺:诚实守信,互惠共赢。我们的经营理念;精益求精,完善品质服务。

我们的工作准则。“坚持 标准,创造时代,追求 品质,争创 。我们的标准: 以人为本,简捷严明。我们的目标:科技。管理规范,我们管理机制的核心内容;“生产 模具,提供 服务”,是我们的。

我们热诚欢迎国内外各界朋友来公司指导,调研业务。体验“诚实守信,互惠共赢”的内涵。选择“小霞模具”,就是选择了技术和诚信共赢,给您的事业带来稳固的品质、持续业务、和谐的发展,以及无限的商机。

公司名称:台州市黄岩小霞模具有限公司

简称1:小霞模具简称2:小霞模具厂3.小霞模具公司

简称4:小霞模具集团简称5:小霞塑料模具简称6:小霞模业

小霞模具有强大设计团队可接受:提供样品,或者,三维图纸,二维图纸,可以报价开模,欢迎您来咨询报价!

浙江小霞实力强大,能:模具制造,产品加工,产品 处理,产品安装,小霞模具能有一系列生产制造服务!

小霞模具专用

小霞模具 :

小霞模具 方式:

温馨提示:

浙江小霞模具 欢迎你来公司指导定做模具。制造塑料注塑模具。

日期:2022-12-19 辉

","gnid":"9b3946a3ce47bc8a0","img_data":[{"flag":2,"img":[{"desc":"","height":"750","title":"","url":"https://p0.ssl.img.360kuai.com/t01a0553e244cd613e6.jpg","width":"750"},{"desc":"","height":"750","title":"","url":"https://p0.ssl.img.360kuai.com/t01d51e304364830f33.jpg","width":"750"},{"desc":"","height":"750","title":"","url":"https://p0.ssl.img.360kuai.com/t0193e71e9cd9b89bd1.jpg","width":"750"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01a09c4e9378b1d13d.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t0137e912f130695011.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01ba4bf9a39b832a86.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t0186e4ed1cf637da03.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t012a9cb5938a1c393c.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t0180becfe934c4b4d1.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t013a36bd3f3e735dd1.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01f6eabf5383038b67.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01cd35a095070837d3.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01e406b8b6f5d20018.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01e9928b6431f4815e.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01c94c2cade33368f9.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01fc1a9069ffa57701.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t013312882dddf99af0.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01b66d46832376ba7b.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01b44992972170bc0e.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01e8bdb42318803536.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01d0a1ba9e21fa5cce.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t011ce8a71de698aaa9.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01fbe1402453204a08.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01856dd896055f6770.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01365b1cfbf787f059.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t015fe800ffab4fa4c9.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01633ea620b78e57b6.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01c67ce79c63017e81.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01b8cca43af20130e5.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01d114bf316aad93e2.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01d89f46520be6dae3.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01aea002ad75cb1ce0.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01b04d07ca46795850.jpg","width":"960"},{"desc":"","height":"720","title":"","url":"https://p0.ssl.img.360kuai.com/t01880c8dae0caffe41.jpg","width":"960"}]}],"original":0,"pat":"art_src_1,fts0,sts0","powerby":"pika","pub_time":1689918280000,"pure":"","rawurl":"http://zm.news.so.com/359b37e07d104436e39ffedf2437dc2b","redirect":0,"rptid":"970551ffbf0c2ff6","rss_ext":[],"s":"t","src":"小霞模具","tag":[],"title":"周转箱模具/注塑成型模具支持定制

贝奚详615如何提高注塑模具试模的成功率 -

韩雷卢14752361242 ______ 1.使试模测试时间长些,以达到稳定熔胶温度及模具温度.2.按所有成品尺寸的过大或过小以调整机器条件,若缩水率太大及成品显得射料不足,也可资参考以增加闸口尺寸.3.各模穴尺寸的过大或过小予以修正之,若西诺模具的模穴与门口尺寸尚属正确,那么就应试改机器条件,如充模速率,模具温度及各部压力等,并检视某些模穴是否充模较慢.4.依各模穴成品之配合情形或模蕊移位,予以各别修正,也许可再试调充模率及模具温度,以便改善其均匀度.

贝奚详615模具试模一般要试几次 -

韩雷卢14752361242 ______ 摘自网上的,希望有用:1. 了解模具的有关资料: 最好能取得模具的设计图面,详予分析,并约得模具技师参加试模工作.2. 先在工作台上检查其机械配合动作: 要注意有否刮伤,缺件及松动等现象,模向滑板动作是否确实,水道及气管接头...

贝奚详615冲压模具试模的时候应该注意什么? -

韩雷卢14752361242 ______ 应该主要冲床的滑块不要下的过深,一般凸模进入凹模有几十丝就可以了.压模具的压板不要顶住模具侧面的台阶,防止模具侧面受力,使模具的间隙不均匀,容易造成模具的啃口.还要主要注意观察模具的上打料,下漏料情况,防止上模打不下来料,或者打料杆过长,下模不漏料或者存料过多 .

贝奚详615注塑机试模时如何调塑件的缩水和尺寸 -

韩雷卢14752361242 ______ 请问是打有多厚或多大得产品?另外是用什么材料做?你可以尝试一下分2-3段射胶,最后一段压力要小,要慢,用位置控制(例如溶胶终点是100mm,射胶位置到20可打满产品,你就第一段位置调整到25mm,第二段位置调整到20mm),射胶时间可长一点.冷却时间试试再用久一点时间试试,可以了再慢慢把时间调快.也可以一出模用自然水泡一泡,看看效果.

贝奚详615注塑模具开模一般试模几次是正常的? -

韩雷卢14752361242 ______ 一般最多三到四次吧,简单的一次就OK了

贝奚详615砂浆试模的检验方法 -

韩雷卢14752361242 ______ 1、砂浆试模应由铸铁或钢制成,内表面应机械加工平面光滑,并不应有任何砂眼或缺陷. 2、试模尺寸70.7*70.7*70.7mm 每边70.7±0.1mm.试模是指在产品开发和制造流程中在产品完成模具制作后、批量生产前所进行的测试注塑步骤.模具...

贝奚详615谁能教我怎么 调试 注塑机 -

韩雷卢14752361242 ______ 新模具注塑成型之前或机台更换其他模具生产时,试模是必不可少的部分 .试模结果结果的好坏将直接影响工厂的后续生产是否顺畅.因此在试模过程中必须遵循合理的操作步骤和记录试模过程中有用的技术参数,以利于产品的批量生产. 试...

贝奚详615注塑模具装配完成之后需要做哪些检查呢?

韩雷卢14752361242 ______ 检查注塑模具的分型面,模具分型面用气qiang吹过之后,确认模具顺畅闭合,方可试模.还需要检查注塑模具是否所有的部件都装配完成,不能丢漏任何一个部件.然后在检查一下注塑模具中是否添加了润滑油,检查一下使用是否顺畅.这些检查工作都是必须要完成的,只有这些检查工作完成,确认无误才说明注塑模具可以正常使用.

贝奚详615模具工程师要会哪些东西? -

韩雷卢14752361242 ______ 我就是做设计的软件上:CAD必须的,出工程图纸用 立体上UG模具用的最多,也有用PROE和CATIA的甚至还有用SOLIDWORKS的,个人认为UG最好用,强大.理论上,首先要懂工艺,比如焊接工艺,铸造...

贝奚详615注塑成型有哪些特点?

韩雷卢14752361242 ______ 注塑成型有哪些特点?注塑成型是一种用之甚广的成型方法,与其他成型技术相比有许多明显的特点:(1)注塑成型的优点1)由于成型物料的熔融塑化和流动造型是分别...